Cask Widge Floats for Fermenting and Serving Using Corny Kegs? – You Can Help

I periodically ferment in 10 gallon Cornelius style kegs. For the most part this works great. They are stainless vessels that aren’t prone to breakage and are pressure capable. The biggest headache is transferring fermented beer. I do this under CO2 pressure and transfer from “liquid out” to “liquid in” on the receiving keg. It usually works ok, but problems arise when there is a lot of trub or if I dry hop a lot. To combat this, I used to have three dip tubes of different lengths. I tried to guess which one was the right length based on the beer. It was always a guessing game that I never exactly won. I either leave good beer behind, transfer yeast and trub or worse get clog during transfer. Worst case scenario is multiple clogs as I I’ve experienced with heavily dry hopped beers.

Update: William’s Brewing has released the Top Draw. Although not identical to the Cask Widge, the Top Draw is a purpose built device that’s designed to do the same thing. It also features stainless steel construction.

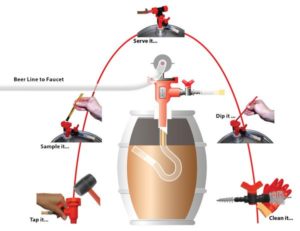

I shared this in some of the forums and got some good feedback and ideas. One post pointed to part of the Cask Widge system as a possible solution. This system, used for serving cask beers, contains a float. It floats on the end of a very flexible piece of tubing and has a screem on the intake part of the float. Beer is transferred out through the float.

Here’s a diagram of how it works in a cask. Replace the cask with a 5 or 10 gallon Cornelius style keg and you get the idea

Here’s a diagram of how it works in a cask. Replace the cask with a 5 or 10 gallon Cornelius style keg and you get the idea

As beer is transferred the float goes down with the beer level. It eventually falls to the bottom of the vessel so that almost all of the beer is transferred.

I was excited about the idea so I looked for a distributor. There is one distributor in the US, but that distributor generally works with commercial establishments and prices are high. At this point, I contacted the owner of Cask Widge. After some some communication back and forth, Cask Widge graciously sent me several floats for testing with Cornelius kegs.

Initial testing in a 10 gallon keg for post fermentation transfer under pressure – I attached a float to a gas out length dip tube placed on the liquid side of a 10 gallon keg. It fit perfectly over the dip tube, no clamp required. Note: this has to be done after the dip tube is installed by reaching through the keg lid. For the first test, I transferred under siphon so I could see what happened to the float. It worked perfectly right out of the box and frankly looked like it was designed for this use.

Since, I’ve used this many times for transferring fermented beer to a 5 gallon keg under pressure. It has worked perfectly for me. The way the float ends up lying on the bottom allows it to transfer nearly everything, all the while leaving trub behind and staying clog free.

The beauty of this, for transferring from a fermenter, is – there is no guessing, just stop transferring at the first sign of trub or when the beer stops. Very little to no trub and very little to no waste. It’s nearly perfect.

I’ve also used Cask Widge floats to serve carbonated beer from a 5 gallon keg. The tubing length needs to be tweaked to get this to work well. The standard tubing size (at least for the Cask Widges I have) is perfect for a 10 gallon keg, but too long for serving from a 5 gallon keg. I trimmed a little tubing off (about a half inch at a time) until I dialed this in. I knew the tubing was too long when the float caught on the side of the keg and beer stopped. A slight shake fixes that.

Advantages of the Cask Widge Float:

- For fermenting, this takes the guess work out of transferring from a Cornelius fermenter.

- For fermenting, Clear, nearly trub free beer is transferred.

- For serving, this seems to provide more resistance. This would allow a higher level of carbonation with the same length of tubing.

- For serving, No chunks in your first pint of beer.

- For serving, Beer is ready and tastes better more quickly. Yeast and other particles start falling out of solution right after transfer to serving keg. Carbonation and settling happen from the top down. The top layers of beer are carbonated and clear the quickest.

- Very little to no beer waste.

A photo of an empty 5 gallon keg after dispensing the entire keg using the Cask Wide Float. Clear pints from beginning to end and it got nearly every drop of beer out of the keg.

A photo of an empty 5 gallon keg after dispensing the entire keg using the Cask Wide Float. Clear pints from beginning to end and it got nearly every drop of beer out of the keg.

A 10 gallon keg used as a fermenter. Clear beer was transferred to the serving keg and trub was left behind. Here is a picture of the trub that’s left at the bottom of the 10 gallon keg used for fermentation.

A 10 gallon keg used as a fermenter. Clear beer was transferred to the serving keg and trub was left behind. Here is a picture of the trub that’s left at the bottom of the 10 gallon keg used for fermentation.

As of this update, no homebrew supply shop has picked this up. Cask Widge is still gauging interest in the US homebrew market for a float marketed to homebrewers for use in Cornelius kegs.

Update: William’s Brewing has released the Top Draw. Although not identical to the Cask Widge, the Top Draw is a purpose built device that’s designed to do the same thing. It also features stainless steel construction.

You Can Help! Are you interested in a homebrew shop picking up the Cask Wide Float for use in Corny Kegs? You can help. Let’s get Cask Widge’s attention!

- Like and Re-tweet this tweet – Cask Wide is tagged in this and should be notified when you re-tweet

- Like and Re-share this Facebook post – Cask Wide is tagged in this and should be notified when you re-share

- Contact MoreBeer – ask them to start carrying the Cask Widge Float and send them a link to this post.

- Contact your favorite homebrew shop and ask them to look into carrying this at a reasonable price.

Looking for a 10 gallon keg? I’d suggest keeping your eye on eBay – 10 gallon kegs

This is a Top Post! See: All Top Posts

pinned

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdealstoppost:caskwidge

I’ve been using the CaskWidge for my 5gal Cornys for over a year now. Even with the standard-length tubing, I don’t have issues with the float getting stuck to the side.

Anyhow, it works great for serving. Haven’t tried in a Corny fermentor yet.

Better pricing would certainly be a plus

Isn’t this the same solution as this though? Clear Draught System. These have been on the market for a while.

Yes, the Clear Draught is same idea. It’s a more complex setup and a bit pricey, but it’s a nice setup at least for serving. I have some and they work great. The biggest issue I see with those is, there’s quite a bit to them including a threaded screw. The cask wide is very simple. I would venture a guess that, they could go for $10 to $15 per pop if a homebrew shop picked them up in quantity.

You can buy just the float from UK Brewing supply in the US

I use the Clear Beer Draft System for this problem. I place the float in the wort while fermenting. I spund. Then transfer until I see trub.

It works great and it’s stainless steel.

there’s a product built for exactly this – Clear Draught

I need one like right now. I have a keg that seems to be clogged …. been messing with it for days

I’d buy 5 right now

Andy, that’s a good application that I had not thought of. This could be used to siphon beer our of a number of vessel types.

This seems like an awesome way filter trub or hops when racking to a secondary or a keg as well. When I dry hop, I usually have to attach a hops bag to end of my siphon to make sure none at tranfered to the keg. From the looks of it, this product could be attached to a siphon to keep the trub in while transfering the beer out.

+1 to the 10 gallon corny keg, where can I get one? I’ve never put much thought into the actual physics of the typical keg setup, but I would love one of these floats. It sucks that the clearest beer is near the finish of a keg and the most hop aroma comes at the beginning. This could solve that. Sign me up.

This product sounds awesome. I have been contemplating cutting my dip tubes for awhile, but this would solve that. Like you said, the better beer is at the top anyway.

Sounds like a great idea. I would love to give it a try.