Kegerator Temperature Probe Placement – To Immerse or Not To Immerse? – three tests to determine optimal placement

Where Should I Place My Kegerator Temperature Probe?

After my test on the effects of a recirculating fan on kegerator temperatures (See: Kegerator Beer Line Temperatures & Reducing Foam with a Recirculating Fan), I decided to test the effects of kegerator temperature probe placement. I went with three configurations: Immersed vs Ambient Non-Immersed vs… Zip Tied to a Beer Can. Those tests yielded some interesting findings.

Related – Our Top Draft Resources!

This article contains affiliate links. We may make a small percentage if you use our links to make a purchase. You won’t pay more and you’ll be supporting Homebrew Finds and more content like this. Thank you for your support!

Test 1 – Zip Tied to a Beer Can

For this test, the probe was zip-tied to a 14.9 Ounce Can of Beamish Irish Stout. This is the technique I’ve used for years. At the time, I wanted something with some mass to help regulate temperature and I didn’t want to have to mess with submerging the probe and the required container of liquid. For this test, the can was placed close to the wall of my keezer on the compressor hump. The second probe was immersed in 500 mL of water in a Lab Container. See the picture in test 2 for more info on placement.

For this test, the probe was zip-tied to a 14.9 Ounce Can of Beamish Irish Stout. This is the technique I’ve used for years. At the time, I wanted something with some mass to help regulate temperature and I didn’t want to have to mess with submerging the probe and the required container of liquid. For this test, the can was placed close to the wall of my keezer on the compressor hump. The second probe was immersed in 500 mL of water in a Lab Container. See the picture in test 2 for more info on placement.

Related: 3 Tips for Keezer Conversions

I also placed a ChefAlarm Thermometer & Timer in my keezer – Hands on Review – as another point of reference, giving me an ambient temperature reading. The ChefAlarm has some great features, including high and low temperature logging. Those highs and lows are what I used as a reference.

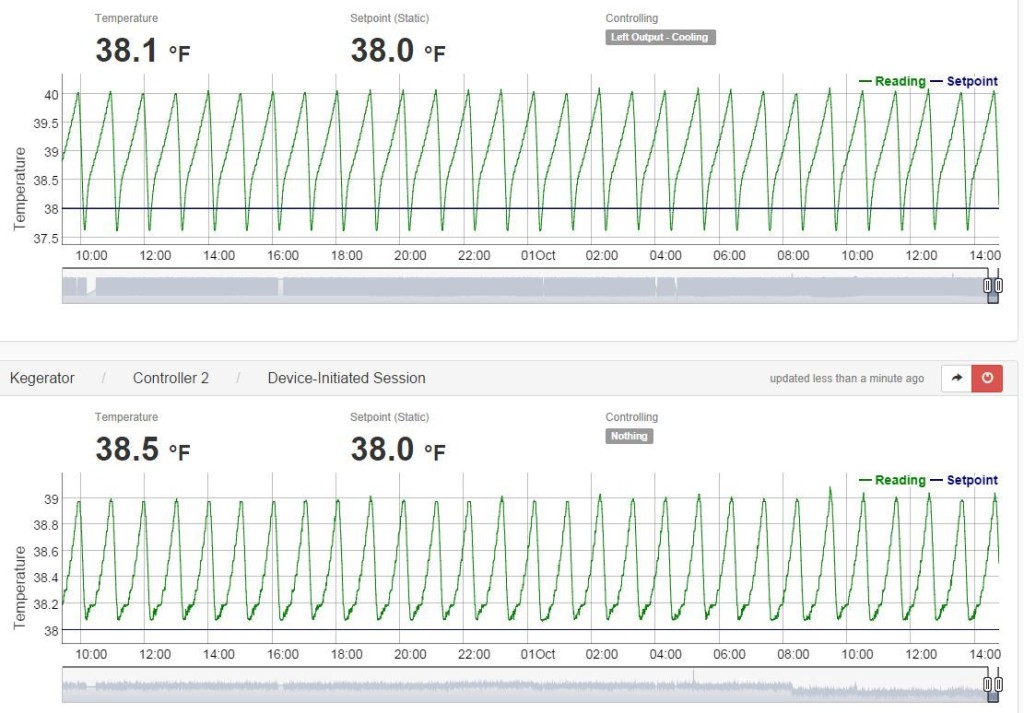

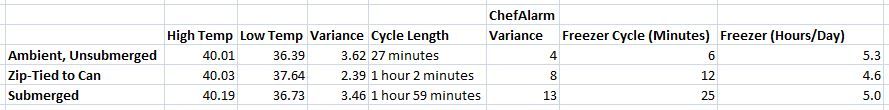

I also placed a ChefAlarm Thermometer & Timer in my keezer – Hands on Review – as another point of reference, giving me an ambient temperature reading. The ChefAlarm has some great features, including high and low temperature logging. Those highs and lows are what I used as a reference. Here are the temperature results for test 1 – zip tied to a can. The top shows the temperature probe zip tied to a beer can. The bottom, for comparison, shows an immersed temperature probe. This method produces and nice clean and reliable reading.

Here are the temperature results for test 1 – zip tied to a can. The top shows the temperature probe zip tied to a beer can. The bottom, for comparison, shows an immersed temperature probe. This method produces and nice clean and reliable reading.

Definitions:

- High Temp: High temperature in deg F as measured by the primary/controlling probe.

- Low Temp: Low temperature in deg F as measured by the primary/controlling probe.

- Variance High to Low: The variance in deg F between general high and low readings from the primary probe.

- Cycle Length: Overall length of one typical cooling cycle, measured from high point to high point.

- ChefAlarm High: Ambient temperature high in deg F as recorded by my ChefAlarm

- ChefAlarm Low: Ambient temperature low in deg F as recorded by my ChefAlarm

- ChefAlarm Variance: Variance in deg F between high and low ChefAlarm readings

- Estimated Freezer Cycle Time: Estimated time that the freezer is running as measured from one high to the following low.

- Estimated Freezer Time: Hours Per Day: Estimation of how long my freezer would run in 24 hours based on frequency of cycles and freezer cycle time.

Results Test 1:

- High Temp: 40.03

- Low Temp: 37.64

- Variance High to Low: 2.39

- Cycle Length: 1 Hour 2 Minutes

- ChefAlarm High: 42

- ChefAlarm Low: 34

- ChefAlarm Variance: 8 degrees

- Estimated Freezer Cycle Time: 12 Minutes

- Estimated Freezer Time: Hours Per Day: 4.6

Test 2 – Submerged Probe

Setup: I placed the probe immersed in about 500 mL of water one of my Bel-Art Scienceware 500 mL Polypropylene Lab Containers. I covered the top with aluminum foil. I have used these containers since 2011 for a bunch of things including yeast rehydration water (see tips page, tip #1), sample storage and more. That container was placed in about the same spot as the can used it test 1. Also Pictured: Eva Dry E-500 – Hands on Review – to handle kegerator condensation.

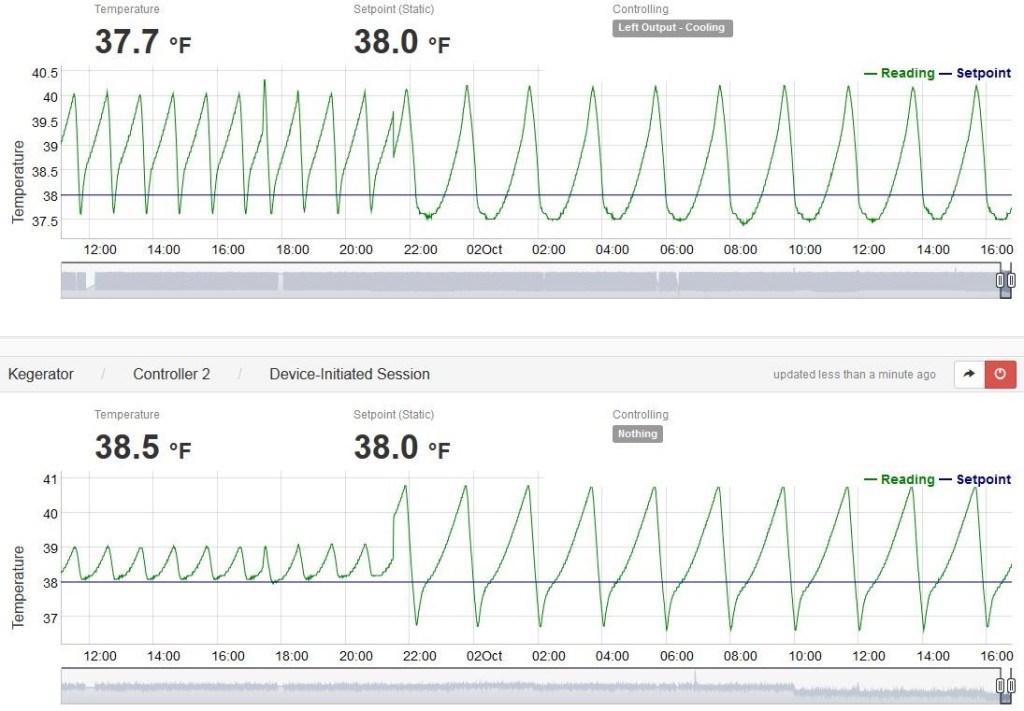

Setup: I placed the probe immersed in about 500 mL of water one of my Bel-Art Scienceware 500 mL Polypropylene Lab Containers. I covered the top with aluminum foil. I have used these containers since 2011 for a bunch of things including yeast rehydration water (see tips page, tip #1), sample storage and more. That container was placed in about the same spot as the can used it test 1. Also Pictured: Eva Dry E-500 – Hands on Review – to handle kegerator condensation. Here are the temperature results for test 2 – immersed. The top shows the immersed temperature probe. The bottom, for comparison, shows the probe zip tied to a beer can. Notice the stuttered temperature changes toward the bottom of this cycle. It doesn’t happen every cycle, but periodically, it also comes close to flat lining. That period of flat lining can last up to 18 minutes. The mass of the water makes temperature readings inefficient. That’s what we want to some degree. We want some sort of a buffer to give a good representation of temperature without quick swings. However the stuttering temperature changes along with flat lining, make me think that this method has it’s drawbacks.

Here are the temperature results for test 2 – immersed. The top shows the immersed temperature probe. The bottom, for comparison, shows the probe zip tied to a beer can. Notice the stuttered temperature changes toward the bottom of this cycle. It doesn’t happen every cycle, but periodically, it also comes close to flat lining. That period of flat lining can last up to 18 minutes. The mass of the water makes temperature readings inefficient. That’s what we want to some degree. We want some sort of a buffer to give a good representation of temperature without quick swings. However the stuttering temperature changes along with flat lining, make me think that this method has it’s drawbacks.

Results Test 2:

- High Temp: 40.19

- Low Temp: 36.76

- Variance High to Low: 3.46

- Cycle Length: 1 Hour 59 Minutes

- ChefAlarm High: 43

- ChefAlarm Low: 30

- ChefAlarm Variance: 13 degrees

- Estimated Freezer Cycle Time: 25 Minutes

- Estimated Freezer Time: Hours Per Day: 5

Test 3 – Ambient Non-Submerged Probe:

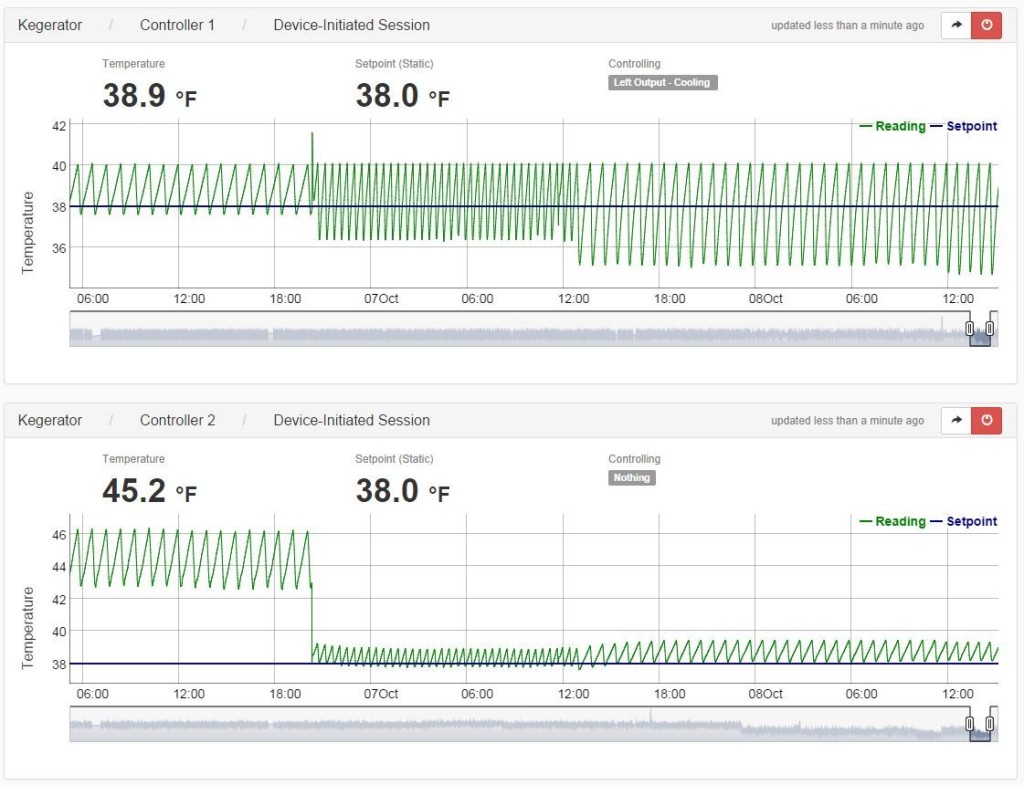

Here are the temperature results for test 3 – ambient, non-submerged. The top of this graph shows the ambient probe, the bottom, for comparison, shows a probe zip tied to a beer can. The left most portion of the graph is part of a previous test, disregard that. The middle portion shows the ambient non-submersed probe with a recirculating fan (or via amazon.ca for Canadian brewers). By the way… all previous tests were completed with a fan. The right portion shows the same test, without the fan. I’m not reporting those results here. That test was much as you would expect it to be. Similar to the fan test, with larger swings and slower cycles. Thoughts… I was actually impressed with the consistency of the ambient air results. When I first looked at the graph, I noticed the semi-wild start of the test and I thought… here we go… this one is going to be all over the place. However, when it settled in, it was very reliable. It also has good accuracy. The difference between the zip tied readings and the ambient readings are small. The downside of this method is how often the freezer kicks on. This method had the shortest cycle length, by far, at just 27 minutes. It also had the highest estimated freezer utilization at 5.3 hours per day.

Here are the temperature results for test 3 – ambient, non-submerged. The top of this graph shows the ambient probe, the bottom, for comparison, shows a probe zip tied to a beer can. The left most portion of the graph is part of a previous test, disregard that. The middle portion shows the ambient non-submersed probe with a recirculating fan (or via amazon.ca for Canadian brewers). By the way… all previous tests were completed with a fan. The right portion shows the same test, without the fan. I’m not reporting those results here. That test was much as you would expect it to be. Similar to the fan test, with larger swings and slower cycles. Thoughts… I was actually impressed with the consistency of the ambient air results. When I first looked at the graph, I noticed the semi-wild start of the test and I thought… here we go… this one is going to be all over the place. However, when it settled in, it was very reliable. It also has good accuracy. The difference between the zip tied readings and the ambient readings are small. The downside of this method is how often the freezer kicks on. This method had the shortest cycle length, by far, at just 27 minutes. It also had the highest estimated freezer utilization at 5.3 hours per day.

Results Test 3:

- High Temp: 40.01

- Low Temp: 36.39

- Variance High to Low: 3.62

- Cycle Length: 27 Minutes

- ChefAlarm High: 39

- ChefAlarm Low: 35

- ChefAlarm Variance: 4 degrees

- Estimated Freezer Cycle Time: 6 Minutes

- Estimated Freezer Time: Hours Per Day: 5.3

Overall Results

Here side by side comparisons of key metrics…

The submerged test produced the longest cycle length, by far. Nearly twice as long as the zip tie test and four times the length of the ambient test. It had middle of the road temp variances (compared to zip tied) but it’s ChefAlarm (ambient air) test showed a whopping 13 degrees difference. Those swings are the result of how much time the freezer has to stay on to overcome the mass of the water used in the immersed test. That mass also causes inconsistent temperature readings and periods of flat lining.

The ambient test produced good accuracy (second best variance and best ChefAlarm ambient air varience) but the short cycle length of 27 minutes means your freezer is kicking on a lot. That shows up in the estimated freezer hours per day… 5.3 hours, the highest of any method.

Conclusions

I think the zip-tied can approach provides a good middle of the road solution. It provides the best accuracy, based on it’s 2.39 degree temp variance, has a middle of the road overall cycle length, middle of the road freezer run time and uses the least amount of energy with an estimated 4.6 hours of freezer run time per day. The can also offers the benefit of not having to mess with containers of water or other liquids. It’s also easy to move and reposition when cleaning or reconfiguring your kegerator.

Related

- Handling Kegerator Condensation with the Eva Dry E-500

- Homebrew Temp Controller Roundup! – Kegerator and Fermentation – concepts, applications and models

- Kegerator Beer Line Temperatures & Reducing Foam with a Recirculating Fan

- AC Infinity LS8038A-X Standard Cooling Fan, 115V AC

- Canada: AC Infinity AXIAL 8038, Quiet Muffin Fan, 115V 120V AC 80mm x 38mm Low Speed, UL-Certified

- ChefAlarm Thermometer and Timer

Some Additional Notes: These tests are with my equipment. Your results will vary based on a lot of factors including freezer/refrigerator, temp controller, amount of liquid used, probe placement, etc. In spite of those variances, I think these tests give you a good general idea about probe placement. I used a BrewBit Model T, sourced via Kickstarter, to log temperature.

Keg Deals!

kegdealsDiagnosing Foam Issues

Rebuild Your Kegs!

Also: Kegerator Tips & Gear | Keg Repair Part #s | Recent Keg Finds

Our Top Draft Resources!

Check our our Top Draft Related Resources- Commentary: Pin Lock Keg Pricing and Availability

- Check Your CO2 Regulator for Leaks!

- How to get a keg ready for first use? New Keg Cleaning and Prep

- Portable Draft Beer Serving Options!

- Pin Lock Keg Pricing and Availability

- The Most Difficult Spot to Check for CO2 Leaks

- Keg O-Ring Materials Selection! – EPDM, Silicone and Buna-N?

- Why Do I Have Bubbles in My Beer Line? Diagnosing and Fixing Kegerator Foam Problems

- Five Benefits of Using Corny Kegs As Fermenters

- Rebuilding & Reconditioning Homebrew Kegs!

- Food Safe Replacement Keg O-Rings in Bulk

- Hands on Review: Kegland DuoTight Fittings & EVABarrier Tubing!

- Why Won’t My Beer Carbonate? Fixing Draft Beer Carbonation Problems

- What Does a Flow Control Faucet Do?

- Upgrade Your Kegerator – 6 Improvements!

- Serve Homebrew on Any Kegerator & Convert Commercial Kegerator to Homebrew

- Tips and Gear for Growler Filling

- What’s the Difference Between Ball Lock Kegs and Pin Lock Kegs?

- Checking for Draft System CO2 Leaks – Using The Pressure Gauge Method

- Tip: Consider Oetiker Stepless Clamps for Kegerator Gas and Beer Lines

- Hands On Review: Inkbird ITC-308 Dual Stage Temperature Controller +WiFi Version

- Universal Poppets Tips and Tricks!

- Convert Your Mark II Keg & Carboy Washer to a Recirculating Draft Line Cleaning Pump!

- Step by Step: Finding and Fixing Keg CO2 Leaks

- Kegerator Temperature Probe Placement – To Immerse or Not To Immerse? – three tests to determine optimal pla…

- Kegerator Beer Line Temperatures & Reducing Foam with a Recirculating Fan

- Kegging CO2 Use Estimations and Calculations

- Balancing Your Kegerator Draft System

- Building a Simple Ball Lock Draft Line Flushing Setup

- Build a Recirculating Draft Line Cleaning Pump

- Home Brew Keg Roundup – New & Used, 5 and 2.5 Gallon & More!

- Damp Kegerator? Fix Kegerator Condensation

- Homebrew Temp Controller Roundup! – Kegerator and Fermentation – concepts, applications and models

- Bulk Keg Orings and Keg Parts Reference

More Homebrew Finds!

- Last 50 Finds!

- Top Deals – a curated list of the best deals

- Homebrew Reviews – one of the largest libraries of homebrew reviews in existence!

- Our Top Posts – tips, how-tos, resources posts and more

- Let’s be Friends!

Recent Deals!

10 Most Recent Homebrew Resource Posts & How-To’s!

We are Homebrew Review HQ! Our 10 Most Recent Reviews

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdealsThis is a Top Post! See: All Top Posts

Make sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions. tag:lnksfxd toppost:probeplacement rs:8 tag:tpr

Did anyone ever compare the probe

Zip tied around the beer can to the koozie around the beer can? If so what were your results? I’d expect the koozie may fall somewhere in between probe submerged in water and zip tied to can.

I’m trying to dial in my edgestar kegerator now with an inkbird and debating what routes best.

Any opinions? Also what cooling differential was used for the inkbird for your study? 3f?

One factor that is missed. Of course, given time, any beer that is in a static state will eventually have a temperature consistent with the ambient temperature.

HOWEVER, I think this experiment neglects that more often than not, homebrewers are using their temperature control for FERMENTATION, and active fermentation is a exothermic process, where the yeast are putting off heat as they actively ferment beer, causing the wort temperature to be 3-5 degrees higher than the ambient temperature.

So, this experiment only means something when there is no active fermentation. During an active fermentation, I would suspect that an immersed probe would be much more accurate than something anywhere outside of the fermentation vessel.

It would be most interesting and relevant to conduct this same experiment on an active fermentation.

This post only addresses temperature probe placement in a kegerator. Maybe I should change the title to clarify that. I think you’ve got a great point with regards to temperature probe place for fermentation.

Nice article! Your work is very helpful and a great start!

It’d be interesting to see what the differential would be for a probe immersed in the a carboy full of liquid using a Thermowell. Thing is you won’t ever heat or cool 5 or so gallons of liquid quickly in a fridge (nor would you want to necessarily). But air is quickly heated/chilled. Fermentation is an exothermic process (not sure how exothermic with lager yeast!) & so you have to take that into consideration. Questions like:

What temperature is the center mass of the fermenting beer? During budding, vigorous fermentation or finishing?

Where is the best ‘middle ground’ to place the probe during these stages?

The Barely Man – Chris. An interesting point about using a thermowell is that the reading of the temperature definitely seems to be affected by the temperature of the entire length of the cord coming to the thermowell from the temperature probe. I have noticed that the ambient temperature of the keezer affects the cord, especially when that temperature probe is placed outside of the keezer (thus the temperature outside of the keezer also affects the reading). I noticed this when I had very inconsistent results while using a thermowell to measure the temperature of the beer as my keezer went through its cycles in a test similar to the above study, but only with regard to ambient temperatures. It would be most interesting to do experiments on this aspect also (i.e. to check the accuracy of the thermowell temperature reading when the cord leading to it, is subjected to different temperatures).

After thinking about this some more, I think insulating the probe on one 5 gallon carboy in a refrigerator set for either 50 or 68 is different than having several kegs in a 15 cu ft keezer (more than 15 cu ft with the added collar) set at 38. I suspect that with the probe tied to the beer can it’s measuring a mixture of can mass temp and ambient. Insulating it would make it act more like the immersed probe and cause the cycle length and time to go up. I assume this is because the ambient temp would have to go up considerably in order for the temperature of the liquid to rise.

Anyway, I’ve been measuring ambient temp so far with a Johnson A419. I have to set at 41 with a differential of 2 degrees to get it to stabilize at 37-38 so it cuts on at 41 and cuts off at 39. Currently its cycling too often. So I’m going to try your technique with the probe tied to a beer can and add a fan and the de-humidifier. How do you have your controller programmed?

Thanks! David

I think you’re right on. On the kegerator, I have it set to a 2 degree differential.

Any reason why you don’t put a piece of Reflectix or similar insulation over your temp probe on the beer can to completely isolate the reading to the can? That’s how I do my fermenter in my fridge. I put the temp probe under a piece of Reflectix insulation and strap to the carboy. I believe it gives a more accurate reading.

This is a great site and great articles. The how-to’s and tips have been very helpful. Thanks a lot!

David

Hey David! Thanks for the nice words! It would be interesting to try. The more mass and insulating you have on and around the probe the slower the controller will be to react. The slower it reacts, the wider the temperature swing will be. I think there is a sweet spot with just the can’s mass. It’s possible a piece of insulation could help the overall pattern, it would be something good to test.

I have a similar setup as David, but instead of reflectix I just use a can koozie. Can of soda in a koozie, and just slip the temp probe down inside. I wonder if that might be worth testing vs. ziptied to a can, see if there is a isolation effect and whether that is better or worse than more ambient exposure.

Great test.

Would you consider these findings a valid starting point when using a freezer with temp control as a fermentation chamber? Or would you be better of relying upon the “tape it to the fermenter in bubble wrap” approach?

That’s a good question and a great idea for another experiment. I wouldn’t suggest changing your fermentation probe placement based on this (yet). I just tape or rubber band the probe to my fermenter for that. I suggest you keep doing what you’ve been doing for now. I’ll put this in the future experiments hopper. Thanks Dean!

I think one thing that you are overlooking is the variance of the temperature with the probe ziptied when controlled by the ambient probe (last image, bottom graph, middle segment). If I am seeing that correctly, there is only a variance of about 1 degree. So while you are cycling your freezer more frequently, you appear to be getting smaller temperature swings in your beer.

Better yet, do all of these tests with the second probe taped to your keg. My guess is that the temperature variance is going to be very small/negligible for all of these methods, meaning go with the easiest/cheapest/best for the life of your compressor.