Setting Economy Inline Regulators with a Spunding Valve

These inline secondary regulators have been on the scene for a little while now. At the price I’ve seen them at, sub $10, they are a bargain. They also add a lot of flexibility to your draft setup, allowing you to easily and cheaply vend using multiple pressures and carbonation levels.

Grab One! via William’s Brewing | via MoreBeer

Note that these are inline secondary regulators. You still need a primary regulator attached to your CO2 tank. The idea is, you set the primary to the highest pressure you will use (without exceeding specifications of any component of your system) and then use these regulators inline (one per line) to fine tune pressure and carbonation [See: Balancing Your Draft System]. As an example, you could set your primary to 25 PSI for faster force carbonation and set each line to a different pressure based on desired carbonation level.

Since this does not have a gauge, you need some sort of a gauge to use for tuning in the pressure. The gauge doesn’t have to stay connected, just while you’re setting the regulator. This is a perfect application of a Spunding Valve [See: Build a Spunding Valve! – How and Why]

Thanks to Facebook Friend Rob [8 Ways to Connect with HBF] for his process for setting the Inline Secondary using a Spunding Valve and for the photo walk through!

Here’s Rob Spunding Setup. It’s a Style 3 [See: Build a Spunding Valve! – How and Why] that features a barb, tubing and a valved QD from MoreBeer

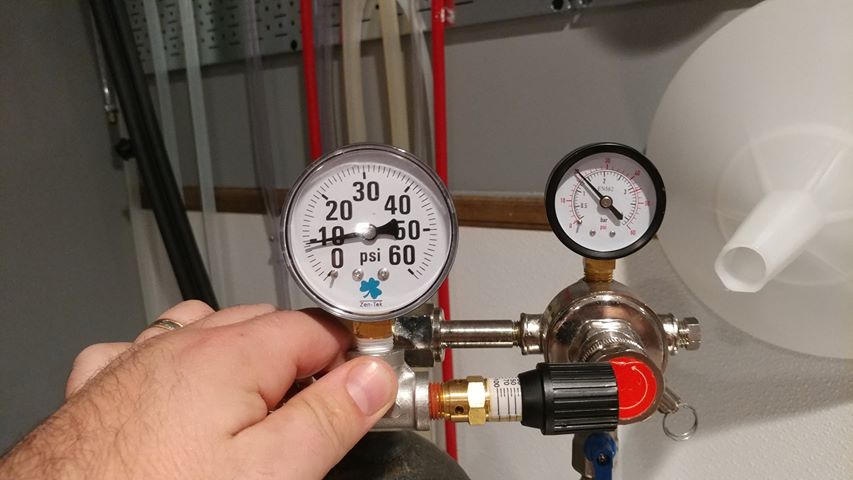

Here’s Rob Spunding Setup. It’s a Style 3 [See: Build a Spunding Valve! – How and Why] that features a barb, tubing and a valved QD from MoreBeer This is the assembly hooked up to the low pressure side of his CO2 regulator. Rob starts with the Spunding Valve set to it’s highest pressure to prevent CO2 from venting.

This is the assembly hooked up to the low pressure side of his CO2 regulator. Rob starts with the Spunding Valve set to it’s highest pressure to prevent CO2 from venting.

With everything hooked up, you have two options:

- Start with the inline regulator fully closed and very slowly work your way up until the Spunding Valve gauge shows reads your desired pressure.

- Start with the inline regulator wide open and slowly work your way down, venting the Spunding Valve as needed until you work your way back down to your desired pressure.

This is a photo of the inline regulator set to about 10 PSI, you can see the primary’s low pressure gauge is set to a higher pressure, 20 PSI.

This is a photo of the inline regulator set to about 10 PSI, you can see the primary’s low pressure gauge is set to a higher pressure, 20 PSI.

This technique has some great benefits. First, many homebrewers already have a Spunding Valve. This process requires little to no extra gear for Spunding Valve owners. Second, this process should use very little CO2. I’ve been adjusting this using a keg. I’ve used an entire empty 2.5 gallon ball lock and also the head space of a keg. Either way, that amounts to more CO2 compared with Rob’s procedure.

Grab The Gear:

- Inline Secondary via William’s Brewing

- Inline Secondary via MoreBeer | Beer & Gas Quick Connect – In-Line Set (With Shut-Off)

Related Posts:

- Build a Spunding Valve! – How and Why

- Hands on Review: William’s Brewing Inline CO2 Regulator

- Balancing Your Draft System

Also: Kegerator Tips & Gear | Keg Repair Part #s | Recent Keg Finds

Our Top Draft Resources!

Check our our Top Draft Related Resources- Commentary: Pin Lock Keg Pricing and Availability

- Check Your CO2 Regulator for Leaks!

- How to get a keg ready for first use? New Keg Cleaning and Prep

- Portable Draft Beer Serving Options!

- Pin Lock Keg Pricing and Availability

- The Most Difficult Spot to Check for CO2 Leaks

- Keg O-Ring Materials Selection! – EPDM, Silicone and Buna-N?

- Why Do I Have Bubbles in My Beer Line? Diagnosing and Fixing Kegerator Foam Problems

- Five Benefits of Using Corny Kegs As Fermenters

- Rebuilding & Reconditioning Homebrew Kegs!

- Food Safe Replacement Keg O-Rings in Bulk

- Hands on Review: Kegland DuoTight Fittings & EVABarrier Tubing!

- Why Won’t My Beer Carbonate? Fixing Draft Beer Carbonation Problems

- What Does a Flow Control Faucet Do?

- Upgrade Your Kegerator – 6 Improvements!

- Serve Homebrew on Any Kegerator & Convert Commercial Kegerator to Homebrew

- Tips and Gear for Growler Filling

- What’s the Difference Between Ball Lock Kegs and Pin Lock Kegs?

- Checking for Draft System CO2 Leaks – Using The Pressure Gauge Method

- Tip: Consider Oetiker Stepless Clamps for Kegerator Gas and Beer Lines

- Hands On Review: Inkbird ITC-308 Dual Stage Temperature Controller +WiFi Version

- Universal Poppets Tips and Tricks!

- Convert Your Mark II Keg & Carboy Washer to a Recirculating Draft Line Cleaning Pump!

- Step by Step: Finding and Fixing Keg CO2 Leaks

- Kegerator Temperature Probe Placement – To Immerse or Not To Immerse? – three tests to determine optimal pla…

- Kegerator Beer Line Temperatures & Reducing Foam with a Recirculating Fan

- Kegging CO2 Use Estimations and Calculations

- Balancing Your Kegerator Draft System

- Building a Simple Ball Lock Draft Line Flushing Setup

- Build a Recirculating Draft Line Cleaning Pump

- Home Brew Keg Roundup – New & Used, 5 and 2.5 Gallon & More!

- Damp Kegerator? Fix Kegerator Condensation

- Homebrew Temp Controller Roundup! – Kegerator and Fermentation – concepts, applications and models

- Bulk Keg Orings and Keg Parts Reference

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdealsMake sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions.

hack:setinlinereg

Very cool! Thanks for posting. However, I got lost with this part: “Second, this process should use very little CO2. I’ve been adjusting this using a keg. I’ve used an entire empty 2.5 gallon ball lock and also the head space of a keg. Either way, that amounts to more CO2 compared with Rob’s procedure.” Can you clarify?