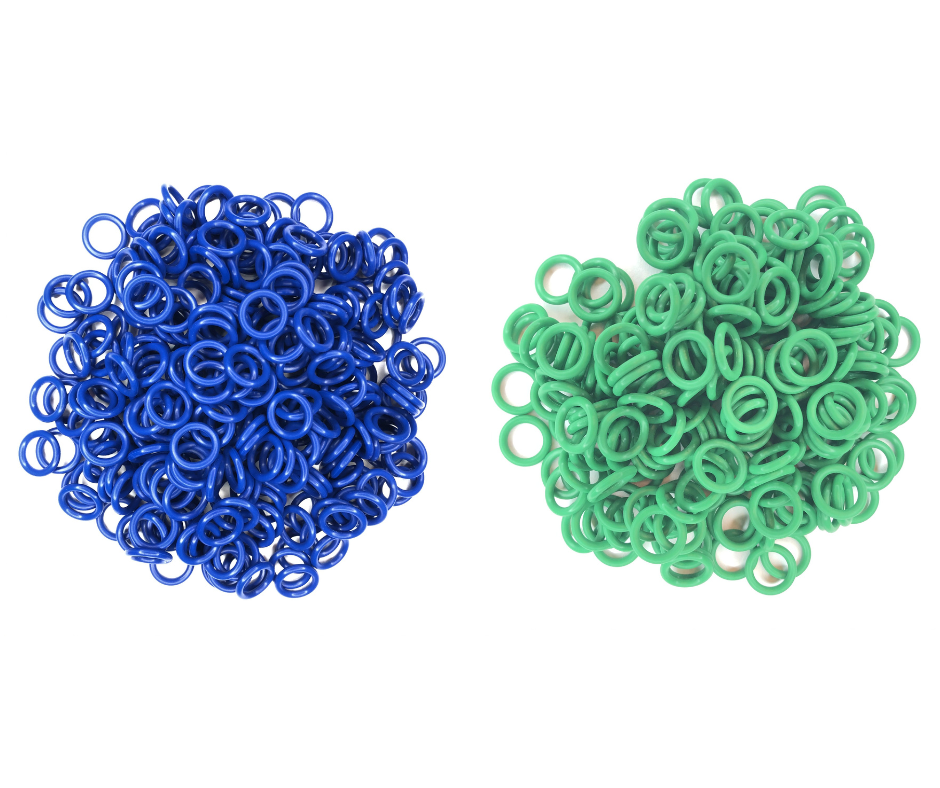

Last Call: Color Code Your Keg Post O-Rings For Easy Identification + Save with STACKING Deals

Valuebrew carries two color schemes to color keg posts. Doing this allows you to quickly identify keg posts. Gray and Black match standard keg QD colors. Blue and Green are meant to be remembered by “Blue for Beer” and “Green for Gas”. All options are made from FDA rated silicone. Since they work equally well on gas and liquid posts you can also mix and match to come up with your own color coding standard.

- Gray & Black Post O-Rings at Valuebrew

- Blue & Green Post O-Rings at Valuebrew

- Just Released: Keg Post O-Rings – Food Safe Silicone – in YELLOW

- All Custom Colors

Custom Color O-rings at Valuebrew!

Save with Stacking Deals…

For a short time, Valuebrew is discounting most of their gear including bulk food grade o-rings (i

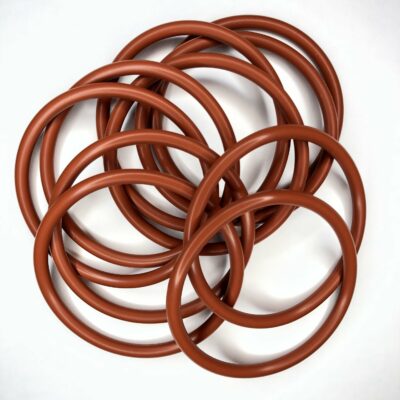

Valuebrew offers a lineup of food grade keg replacement o-rings in bulk quantities. Most offerings are silicone or EPDM with one Buna-N option. Everything they carry is food grade, more info below. They have some unique offerings like bulk pin lock size post o-rings, replacement universal poppet o-rings, bulk internal QD o-rings and color coded Blue and Green post o-rings

Some of these offerings are detailed in our Keg Rebuild How-To

Save an EXTRA 15% when you spend $30 or more on select items at Valuebrew. This stacks on top of existing discounts. Includes…

- Bulk Food Grade O-rings

- Custom Color Post O-Rings

- FDA Rated EPDM O-Rings!

- Universal Poppets

- Ball Lock Jumpers

- DuoTight Compatible Gear

Use coupon code colorcode4u with an order of $30 or more to get the deal

Some Old Dip Tube O-rings Were in Rough Shape

Some Old Dip Tube O-rings Were in Rough Shape

Thanks to John for the

Thanks to John for the