White Labs recently announced new PurePitch yeast packaging for homebrewers. The new packaging goes hand in hand with a new propagation method White Labs is calling the Flexcell Process.

White Labs Description of Flexcell:

Instead of traditional stainless steel fermenters, the patent-pending FlexCell process allows White Labs to propagate yeast with no exposure to the environment all the way to packaging, ensuring its quality and purity.

More about PurePitch Packaging:

- Since the yeast is grown and packaged in the same material the new PurePitch packaging is actually a part of the fermentor, and its contents have never been exposed to the environment.

- PurePitch Packaging is breathable and allows CO2 to escape. Reduced chance of gas build-up.

- This packaging will maintain the yeast in a more stress-free state.

Look for new PurePitch Packaging on Homebrew Finds – connect with HBF – when it’s released sometime this fall.

As part of the release of PurePitch Packaging, Dr Chris White PhD, President and CEO of White Labs wanted to hear directly from Homebrew Finds Readers. We asked you for your questions about the new packaging and yeast and fermentation in general back in July. Questions and answers follow.

Thanks to all who submitted questions and thank you to Dr Chris White!

Look for new PurePitch Packaging on Homebrew Finds when it’s released sometime this fall.

Q 1. When White Labs propagates yeast, what measures are taken to ensure that no mutations take hold?

A. Our attention for looking for mutations hasn’t changed with the new technology. We built a big back end to our yeast production at the beginning. We have a specialized team that works with freezes – check for mutations, by specialized plating, genetic analysis and performance. We are constantly checking for mutations. In addition we minimize time we have yeast on plates and our propagation is limited to 17 days. These tools and personal that separates us from being a yeast propagator and we maintain these yeast in there integrity is one of our missions.

Q 2. Gluten-free brewers are mostly restricted to dry yeast strains, because liquid yeasts are shipped in a medium that contains gluten. Is the PurePitch packaging gluten free, or is it still the same as before?

A. The yeast within the PurePitch packaging is the same as before. We do, however, carry a product called Clarity Ferm, which can help reduce gluten to under 10 ppm in beer.

Q 3. What are the ideal mash parameters, yeast strains, and fermentation temperatures to accentuate each of the following ester/phenol characters in a hefeweizen: clove, banana, and bubble gum?

A. Hef yeast strains that we have are selected to maximize these characteristics. Anything that encourages yeast growth will increase those 3 flavors. Pitching less and higher fermentation temperature that encourage growth are 2 examples. Aerating less will also encourage growth – another parameter that can increase esters.

Q 4. What yeast or blend of yeasts would you recommend to try and recreate keeping at home?

A. If traditional methods are followed for keeping our WLP775 WL cider yeast is the best choice.

Q 5. Is it possible to dry yeast at home for storage and later use?

A. You will get very low viability dry yeast at home, so it’s not recommended. If you did, you would need to check the viability after rehydrating.

Q 6. Would it be possible to make a Servomyces substitute at home? If so, could you suggest how it could be done?

A. No, it is not, as it’s a patented process.

Q 7. The new packaging says it’s breathable so it allows co2 to escape. Even though it’s breathable- I would think if the package is sealed the yeast would be under considerable pressure during reproduction and may have a negative effect on yeast health during its growth. Is that not really a factor or is it accounted for somehow?

A. During the propagation, the vessel is constructed with blow-off valves to allow all of the pressure to escape while the culture is being oxygenated and growing.

Q 8. Is the new packaging permeable to oxygen? If so does that negatively affect the shelf life of the product?

A. We are still conducting trials to test the shelf life, but initial trials indicate the

shelf life may even be prolonged.

Q 9. As temperature fluctuates there is the chance the package will also take in outside air. Especially for people who get yeast delivered in warm months. The yeast temperature fluctuate from cold to warm and back to cold. Have you done tests to see how much outside air gets in and it’s effect on the yeast?

A. The film technology is only allowing gas pressure to escape, but not the other way (like a one-way check valve)

Q 10. You indicate the packaging material is recyclable. What material is it made of as some states have restrictions?

A. #2 plastic

Q 11. Will the new packaging have more strain specific information regarding optimum conditions?

A. Yes, we’ve broken the yeast strains into categories with more specific strain-related recommendations, including Brett/Bacteria. We grouped them into 6 different strain styles. Within the 6, we have specific information for example, like Lagers. The 6 strain types are differentiated by color on the package. Furthermore we are actively pertaining more information on our strains via our tasting room and brewery to add more information to our yeast descriptions that are found online and printed material.

Q 12. How is a uniform cell count, or a known cell count, maintained in each unit when the culture is packaged using this new packaging technology?

A. We’re using automated cell counting technology to validate the consistency of the culture prior to final packaging.

Q 13. Was there an issue with the old packaging that prompted for the redesign (I understand the improved packaging for retailers to take up significantly less shelf space, but was it a yeast reason or was this a response to increases in vial costs or actual issues with the old storage methods?) Will this keep yeast more viable for longer periods of time?

A. This was prompted to reduce the amount of transfers yeast makes to be propagated, concentrated, tested and packaged. From our first thoughts of this process, it was driven by the desire to make better yeast. We have always liked the vial, but we didn’t want that to cloud our desire to make better yeast. By utilizing this new technology, we can offer yeast that has never been exposed to the environment. We have seen better viability over time as well, which is due to release of CO2 and from less time and handling to fill packages.

Q 14. You sell ~100 billion cells per package. These packages include instructions indicating they are directly pitchable into 5 gallons of wort up to ~1.060. However, every brewer of any experience seems to accept as gospel that yeast starters are required for nearly any batch – Jamil Z.’s online calculator claims that 100 billion cells are barely enough for 5 gallons at 1.034, for example. Why, then, has White Labs not marketed a package of 200 or 250 billion cells for homebrew use? This would allow homebrewers to brew beers in the meat of the homebrewing space – say 1.050 – 1.075 – without the trouble of making starters for every batch.

A. We are actually increasing the number of cells per package to 2.5 to 3 billion cells per ml. And laboratory grown yeast won’t necessarily follow the pitching rate guidelines since they are very healthy. The pitching rate recommendations traditionally refer to re-pitched yeast. Also, you are not getting a lot of growth from a starter unless it is an adequate size.

Q 15. The number of cells in each pack strains the minimal requirements for a 5 gallon session strength beer (ie. 250,000 cells/ml/P). And that’s given 100% viability, which is almost never likely due to unavoidable transportation and long term storage issues at LHBS. With the new packages will there be options for larger volumes, (e.g. 200e9 cells) to help address these? Minimal costs additions, offset by new pack savings, would definitely drive market share higher.

A. See answer to #14. With yeast it is similar to beer pricing, if you buy 1 liter of beer it is usually only slightly less than the price of 2 pints, because you have to make twice as much on the manufacturing side. But we are open to different sizes in the future, it just won’t be as ‘less

expensive’ as people might think. Please keep the feedback on sizes coming to White Labs.

Q 16. What temperature should I make a yeast starter at? Room temp, warmer or cooler?

A. Room temperature or warmer (close to 75F or 24C)

Q 17. How long should I let a yeast starter run on a stir plate? Is there a recommended duration, or some visual indication that the colony is ready?

A. 24-48 hrs. The only visual confirmation you can get would be to count the yeast and examine them under the microscope.

Q 18. Should I drain the starter wort first? Should I chill the starter to help it settle before doing so?

A. It is mostly personal preference but if you are decanting the starter wort you should let it settle and chilling it will accelerate that.

Q 19. What temperature should I pitch at? At target fermentation temperature, or some measure below?

A. We recommend pitching at 70, then bringing the temp down to fermentation temperature when fermentation begins.

Q 20. Can I over do it with oxygen in the wort when I pitch my yeast? I have been doing some experiments with extending the time that I run O2 on my wort when I pitch. I have a commercial size O2 tank & regulator and .5 micron stone that I use to oxygenate my 10 gal all grain batches. I noticed that increasing my O2 run improved the start on my ferment and produced better all around results. So, I started extending the time that I ran my o2, just to see what would happen. I expected to see a point where my results started to fall off. This did not seem to happen. I continued to extend my oxygenation up to about 35 minutes at about 1 liter per minute. I do not have the equipment to do cell counts and so my results are fairly subjective, but, it seems to me that at least up to 15 minutes I observed improvements in fermentation. Can I hurt the cells with a 15 minute O2 run and at what point am I just wasting my time. Using the large o2 cylinder, the cost is very minimal and I am not concerned with it. My primary interest is producing better beer. What will make my yeast perform best?

A. In homebrew set ups, it is very hard to over oxygenate. Once saturation is reached, excess oxygen will not go into solution. So at that point extra oxygen will be wasted. In commercial operations, they sometimes get over oxygenation because they are oxygenating in line, which can create over pressure which allows more oxygen to dissolve into solution.

Q 21. In your book you mention how important adding oxygen to wort for proper fermentation. Is there a specific amount to add correlated to original gravity? Such as X liters for 5 gallons of 1.040 and Y more for every increase of 5 points?

A. It is not about flow rate of oxygen, that will be different for every set up and every beer. What you want is 8 to 10 ppm of dissolved oxygen in the wort. The difficult part about knowing that is most people do not have the equipment to measure dissolved oxygen.

Q 22. Any brewer who’s tasted their wort knows it tastes much more bitter than the beer it is eventually turned into by yeast. To what extent is the pre- and post-fermentation IBU difference dependent on yeast strain? If it does vary by yeast strain, do you think this would be a useful value to include in each yeast’s spec sheet?

A. Yes, it is affected by different yeast strains. We have been studying this in our brewery/tasting room, and are working on a publication to make this information available to everyone.

Q 23. Will White Labs be able to produce consistent yeast blends with this new method of packaging?

A. Yes

Q 24. Will the work with Yeast Bay migrate over to the new packaging?

A. Yes

Q 25. Will the new method of packaging effect cell counts of Bret and Lacto?

A. No, the cell counts will remain the same

Q 26. Is it possible to clean up a batch of yeast using water purification drops (the kind used for camping)? What are the chances of killing the yeast or reducing its abilities?

A. No, the yeast would be killed.

Q 27. When making high-gravity beer can I viably use distiller’s yeast in the secondary fermentation chamber after the primary yeast has done most of the work to lower the FG a little further?

A. You can always try it but not all distiller’s yeast are considered high gravity yeast

Related:

This is a Top Post! See: All Top Posts

pinned

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdeals

toppost:qandachriswhite

I have this fan and use it in kegerator as a recirculation fan.

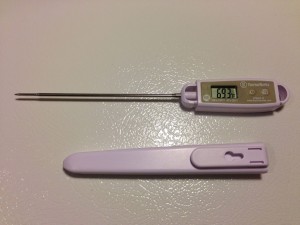

I have this fan and use it in kegerator as a recirculation fan. The setup. I have two temperature probes in my kegerator. One is zip-tied to the top of a beverage line. The other is zip-tied to a can of beer. That’s how I have kept the probe in my kegerator for a long time with the thinking that the mass of the can of beer will help to stabilize temperature readings and give overall stable and accurate readings. That can is sitting on the compressor hump of my Kenmore Deep Freeze (8.8 Cu ft Model 16932, out of production). That puts it about mid keg.

The setup. I have two temperature probes in my kegerator. One is zip-tied to the top of a beverage line. The other is zip-tied to a can of beer. That’s how I have kept the probe in my kegerator for a long time with the thinking that the mass of the can of beer will help to stabilize temperature readings and give overall stable and accurate readings. That can is sitting on the compressor hump of my Kenmore Deep Freeze (8.8 Cu ft Model 16932, out of production). That puts it about mid keg.

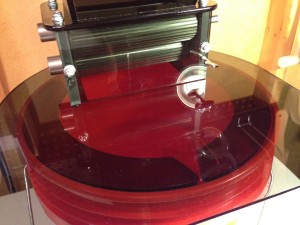

The Captain Crush Grain Mill

The Captain Crush Grain Mill