Updated: December 12, 2024

Benefits of Fermenting Under Pressure

Pressurized fermentations are becoming increasingly popular, and for a good reason. Some of the benefits that you gain from fermenting beer under pressure are: Lower ester production, being able to ferment at higher temperatures without producing off-flavors, and having your beer carbonated by the end of fermentation. Pressure fermenters are also called uni-tanks because you can use them for both fermentation and carbonating. You can serve beer directly from uni-tanks, counter pressure fill bottles or easily transfer beer into kegs using pressure.

Limited Time Deal Save on WilliamsWarn BrewKeg via Blowout Sale!

MoreBeer has a massive early holiday sale going on as of this posting. Over 100 products are discounted. Check sale page for selection and availability.

MoreBeer Blowout Sale!

WilliamsWarn BrewKeg12.5 is included in the mix and on sale for $382.49 while the sale lasts

Limited Time Deal on 15 Gallon Kegs (can be used as a pressure fermenter)!

Torpedo Keg | Ball Lock Keg | Stainless Steel Corny Keg | 15 gal.

More Info

From the product description, check product page for current description, price and availability:

This used Torpedo ball lock 15 gallon keg has the same great features and superior quality as its predecessors, and will allow large-scale homebrewers to fit their entire batch into a single keg. These kegs are laser welded by an ISO certified commercial keg manufacturer, so you won’t find any nooks or crannies for contaminants to hide. Made with rolled stainless steel handles that are comfortable to grab. “In” and “Out” are etched near the keg posts for a quick and mistake-free set up when connecting lines in a refrigerator or kegerator. The 15 gallon kegs can be stacked on top of each other with ball lock fittings still attached.

Specifications:

Total Capacity: 15.2 gal.

Max Pressure: 130 psi

PRV Rating: 85 psi

Height: 24.75″

Diameter: 16.05″

Made from 304 Stainless Steel

Shipping Box Dimensions: 25-3/4″ H x 18″ L x 18″ W

Weight: 32.16 lbs

These kegs are used but in excellent condition. I have a good number of these but when they are gone they are gone and tough to find. They have only been rinsed and examined during refurbishing so Corny Keg recommends that you clean and sanitize before use. The kegs pictured are stock photos of new kegs but these used kegs look great and will perform like new or we will take them back.

- cornykeg,com has a limited number of used 15 gallon Torpedo Ball Locks.

- These are selling for $175. That’s a bargain for a 15 gallon keg!

- Quantities are limited, check the product page to see if you can still get in on this.

Used Torpedo 15 Gallon Ball Lock Corny Keg

Hands on Review! Check out my in depth Hands on Review of the 10 gallon version of this keg.

Compare, New at MoreBeer: Torpedo Ball Lock Keg – 15 gal. KEG815

Related: Benefits of Using Kegs for Fermentation

Fermenting lagers under pressure is a huge benefit of uni-tank. When yeast ferment under pressure, the production of fruity esters is greatly reduced. This can allow you to brew a lager at 70F an obtain traditional lager flavor. – via MoreBeer

Since off-gassing is reduced added hop flavor and aromas are also potential benefits of fermenting under pressure.

This article is by Homebrew Finds Contributor Brad Probert. Brad is an engineer, expert homebrewer and experienced reviewer. Grab a link to Brad’s website at the end of this review.

What is Fermenting Under Pressure?

I’ll start first by defining “normal fermentation” as fermenting with an airlock or blow-off tube on your fermentor. In the chemical process of your yeast converting wort sugars to alcohol, CO2 gets naturally produced. In a normal fermentation, this CO2 pushes out of the liquid wort/beer into the headspace above your liquid level. As more and more CO2 gets produced, it starts to get crowded up there, so pressure builds up and then pushes a glug of air/CO2 through your airlock. As fermentation progresses, more CO2 is created, creates pressure in the headspace, and then vents through your blow-off tube or airlock.

Fermenting under pressure follows the chemical process, but instead of an airlock or blow-off tube, which has a very low pressure threshold before it relieves the pressure, you have a spunding valve attached. The spunding valve is typically set to open and release headspace pressure until a much higher level, and therefore keeps everything at a higher pressure in your fermentor (headspace and beer). This increased pressure on your yeast during fermentation changes how they behave. The two main important things that happens with yeast under pressure are: 1) It slows down fermentation rate, and 2) It suppresses production of esters and fusel alcohols.

Spunding Valves for Fermenting Under Pressure

There are multiple makers of spunding valves, with different looks and features/limitations. They can be grouped into two major types- 1) Spring & Poppet, and 2) Diaphragm. Both operate with the same basic principles. Pressure from your fermentor pushes up against the pressure regulating mechanism inside. In the Spring & Poppet, the “mechanism” is a small poppet like what you have inside the gas or liquid posts on your keg. The Diaphragm design uses a large flexible rubber/silicone disc as its “mechanism”. Resisting this pressure, on the other side of the mechanism is a spring. By turning an adjustment knob on the spunding, you can compress the spring more, which in turn pushes harder on the mechanism. Then it’s just a force balance between the pressure in your fermentor and the compression of the spring. Once the pressure overcomes the spring force, it creates a path for the compressed CO2 to escape and it bleeds off. This then regulates your pressure.

Keep Reading: Lots More About Fermenting Under Pressure

The USV20 fresh out of the box

The USV20 fresh out of the box A look inside. It came with manuals, vacuum sealer bags, a quick start guide and a vac sealed toy avocado.

A look inside. It came with manuals, vacuum sealer bags, a quick start guide and a vac sealed toy avocado. A look at the contents

A look at the contents

In the package. As of this posting, this comes in singles with the option to add a second on for a reduced cost. Check the product page to see if that’s still available.

In the package. As of this posting, this comes in singles with the option to add a second on for a reduced cost. Check the product page to see if that’s still available. A look down the jumper. You’ll notice a stainless steel bar. This jumper doesn’t have traditional poppets. Instead these bars take their place enabling connected ball lock QDs to open when connected. This is actually a really good feature because it means the jumper is open to the air when unused and can be clean, dried and sanitized.

A look down the jumper. You’ll notice a stainless steel bar. This jumper doesn’t have traditional poppets. Instead these bars take their place enabling connected ball lock QDs to open when connected. This is actually a really good feature because it means the jumper is open to the air when unused and can be clean, dried and sanitized.

Bag o’ stuff

Bag o’ stuff This is what you get with the basic pump. Tee, carbonation cap, pump and dip tube.

This is what you get with the basic pump. Tee, carbonation cap, pump and dip tube. I installed this on a 2L bottle. You’ll notice the carbonation cap has changed colors. I used one I already had (Kegland brand, just a different color), because I already has a dip tube trimmed to size and installed from a recent update to

I installed this on a 2L bottle. You’ll notice the carbonation cap has changed colors. I used one I already had (Kegland brand, just a different color), because I already has a dip tube trimmed to size and installed from a recent update to

Complete test setup

Complete test setup Ball Lock QD Installed on the pump assembly

Ball Lock QD Installed on the pump assembly It’s a little difficult to see but… it works. With some pumping, I got a slow steady stream of liquid. Keep in mind this is cleaning two 10′ lines at the same time.

It’s a little difficult to see but… it works. With some pumping, I got a slow steady stream of liquid. Keep in mind this is cleaning two 10′ lines at the same time. Add on a ball lock faucet and you’ve got a portable serving keg without paying for expensive CO2 cartridges. Before you email me/comment/etc… yes this will cause oxidation, I would not suggest this as a long term solution. Only for the occasion that you and your friends will be able to drink an entire growler in an evening. Oxidation won’t have enough time to become a factor. Use another solution for longer term applications.

Add on a ball lock faucet and you’ve got a portable serving keg without paying for expensive CO2 cartridges. Before you email me/comment/etc… yes this will cause oxidation, I would not suggest this as a long term solution. Only for the occasion that you and your friends will be able to drink an entire growler in an evening. Oxidation won’t have enough time to become a factor. Use another solution for longer term applications. Remove the tee, add a

Remove the tee, add a  Replace the pump with another carbonation cap, use a 2.5 liter bottle and… you have a 2.5 liter keg you can use in your kegerator!

Replace the pump with another carbonation cap, use a 2.5 liter bottle and… you have a 2.5 liter keg you can use in your kegerator!

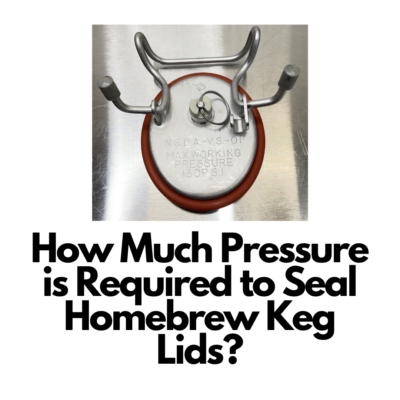

A closer look at the handle and lid. This lid (like most ball lock style lids) is equipped with a manual PRV. Generally speaking… Both Ball Lock and Pin Lock style lids are the same dimension and are interchangeable. You can use a Ball Lock Lid on a Pin Lock Keg and vice versa. A big difference are the PRV (pressure relief valve) functions between the two styles. Both have automatic safety PRV valves. That is, if the pressure gets too high, both will automatically vent for safety reasons. The difference is in manual PRV functionality. Ball Lock Keg lids have a pull ring that allows you to manually vent the keg as you’d like. You may want to do that for the purpose of removing the keg lid or to vent excess pressure in an attempt to get down to a lower pressure. See:

A closer look at the handle and lid. This lid (like most ball lock style lids) is equipped with a manual PRV. Generally speaking… Both Ball Lock and Pin Lock style lids are the same dimension and are interchangeable. You can use a Ball Lock Lid on a Pin Lock Keg and vice versa. A big difference are the PRV (pressure relief valve) functions between the two styles. Both have automatic safety PRV valves. That is, if the pressure gets too high, both will automatically vent for safety reasons. The difference is in manual PRV functionality. Ball Lock Keg lids have a pull ring that allows you to manually vent the keg as you’d like. You may want to do that for the purpose of removing the keg lid or to vent excess pressure in an attempt to get down to a lower pressure. See:

Contents of Kit

Contents of Kit Description of Box Contents

Description of Box Contents

Close-up of the box. Part number KL19859, Compatible with

Close-up of the box. Part number KL19859, Compatible with

Fermenting in a Keg Using TC Equipped Lid

Fermenting in a Keg Using TC Equipped Lid

TC Equipped Lid with Butterfly Valve – Also:

TC Equipped Lid with Butterfly Valve – Also:

The AC Power Adapter. This unit requires power. I believe that’s related to the tankless aspect of this filter’s design. My assumption is that It has a pressure pump that drives water through the filtration system to deliver a reasonable on-demand performance. The advanced filter tracking features and built in TDS sensor also require power.

The AC Power Adapter. This unit requires power. I believe that’s related to the tankless aspect of this filter’s design. My assumption is that It has a pressure pump that drives water through the filtration system to deliver a reasonable on-demand performance. The advanced filter tracking features and built in TDS sensor also require power. Required tubing and fittings

Required tubing and fittings