16 Oz Star San Homebrew Sanitizer – on sale for $19.88 + Why I think this size is plenty large enough

Five Star – Star San – 16 Ounce – Brew Sanitizer

More InfoHighlighted Features

- HIGH FOAMING- This sanitizer produces foam with little agitation for penetration into those cracks and crevices of equipment

- CONVENIENT NO-RINSE FORMULA- With only a 30 second contact time, this sanitizer doesn't need to be rinsed off When left to dry on stainless steel at certain concentrations, it will passivate and protect the equipment

- SAFE AND EASY TO USE - Comes in an easy dosing dual-neck bottle with built-in measurements

- EFFECTIVE ON MANY SURAFACES- Great for use on carboys, kegs, fermentors, kettles, brewing systems, chillers, and heat exchangers

- USED BY PROFESSIONALS- Many craft brewers choose Star San as their sanitizer of choice in order to make good beer

Star San is my sanitizer of choice. It is effective, food safe and no-rinse. It is also very cost effective if you use the spray bottle method. See: Star San Tips, Tricks and Guidelines – Using Star San In a Spray Bottle

3/20 5 PM Central: This is on sale for $19.88. Shipping is also free to many US addresses with Prime Membership [Try Prime for Free] or a qualifying order. Prices and availability can change quickly. Check product page for current info – More About Prices

Five Star – Star San – 16 Ounce – Brew Sanitizer High Foaming Acid Anionic – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

I think this size is plenty….

Considering the shelf life of Star San concentrate is 1 to 2 years, If you’re using the Spray Bottle Method [See: Tip: Star San Tips, Tricks and Guidelines – Using Star San In a Spray Bottle], I generally recommend purchasing the 8 ounce size. 8 ounces of concentrate yields about 39 gallons of mixed solution. The spray bottle method is very efficient, so you don’t end up using much sanitizer per batch. Let’s say you use 1/4 gallon (which I personally think is high) for each batch, the 8 ounces size yields enough mixed solution for around 157 batches. That figures to about 13 batches per month over a 1 year period. If you use 1/8 gallon (which I think is more realistic) that equates to about 26 batches per month over a 1 year period. The larger 16 and 32 ounces sizes may be a lower cost per ounce, but if you’re unable to use it within Star San’s shelf life, you’ll just be throwing sanitizer away or using less effective past date sanitizer. Getting a smaller bottle more often means your Star San is fresher.

Those estimations are for 8 ounces, double the numbers for 16 ounces.

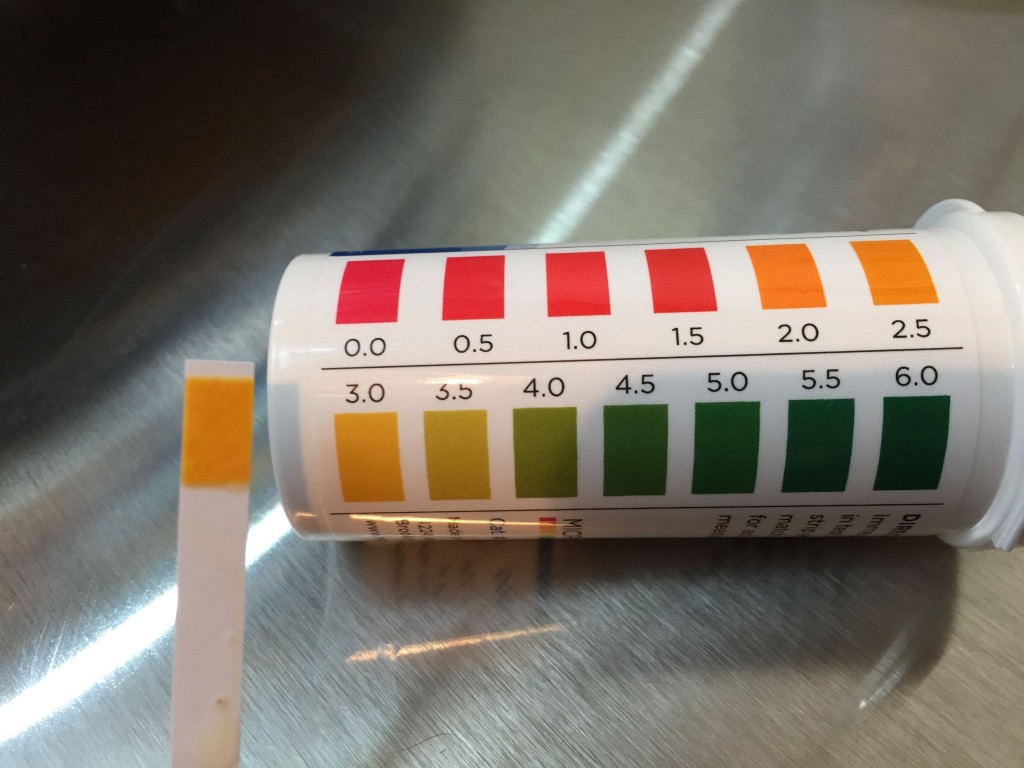

![pH Test Paper for Kombucha Brewing, 0.5 to 5.5 pH [16 Foot Roll with Dispenser]](https://www.homebrewfinds.com/wp-content/uploads/2020/10/61K2Zt2IvzL._SL1000_-350x350.jpg)