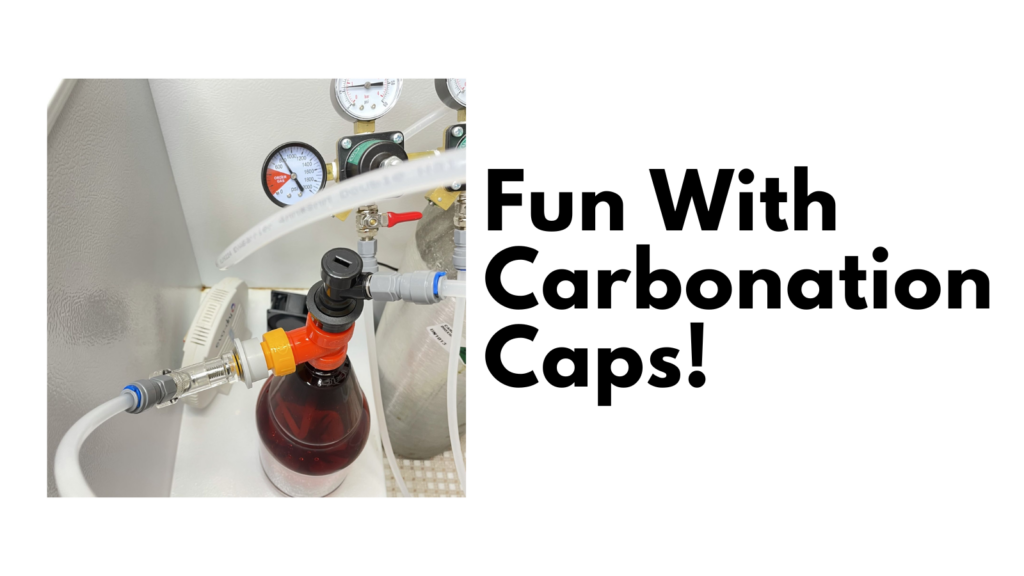

Fun with Carbonation Caps!

Carbonation caps are available in a number of styles and materials from various manufacturers. These are generally designed to thread into standard 1L and 2L PET bottles.

Limited Time DEAL – William’s Brewing Gas Distribution Parts Sale

- For a limited time William’s Brewing is discounting their entire lineup so gas distribution parts by 15%. This includes manifolds, carbonation caps, tees, and lots more.

- No coupon code required, add to your cart to see discount.

- Shipping is free or reasonably priced flat rate to addresses in the contiguous US depending on your order size for most items.

The lineup includes multiple carbonation cap and tee offerings

Sourcing a Carbonation Cap

Works with both liquid and gas (double check current specs to confirm) – Ferroday Stainless Carbonation Cap Counter Pressure Bottle Filling With 5/16″ Barb – Hands on Review

Works with both liquid and gas (double check current specs to confirm) – Ferroday Stainless Carbonation Cap Counter Pressure Bottle Filling With 5/16″ Barb – Hands on Review

- Ferroday Stainless Carbonation Cap Counter Pressure Bottle Filling With 5/16″ Barb – Hands on Review

- Stainless Carbonation Cap with 5/16″ Barb Ball Lock Type, Fit Most Soft Drink PET Bottles

- UP100 Line Cleaning Cap Stainless Carbonation Cap Counter Pressure Bottle Filling,w/ 5/16″ Barb

- 3pak PLASTIC CARBONATION & LINE CLEANING CAP,Carbonation Cap 1/4″ Barb, Ball Lock Type, Fit Soft Drink PET Bottles

- MRbrew Plastic Carbonation Cap, 3 PCS Ball Lock Keg Post 5/16” Beer Line Nipple Barb Homebrew Kegging Soft Soda Drink PET Bottles Counter Pressure Bottle Filling Cap with Spare Sealing Gasket O-rings

- MRbrew Plastic Carbonation Cap, 3 PCS Ball Lock Keg Post 5/16” Beer Line Nipple Barb Homebrew Kegging Soft Soda Drink PET Bottles Counter Pressure Bottle Filling Cap with Spare Sealing Gasket O-rings

- New offerings regularly pop up. Search Amazon for “stainless steel carbonation cap” to see what’s out there.

Tee Fittings

- Carbonation, Beer Brewing Carbonation Adapter 304 Stainless Steel Thread Conversion Connector Adapter Tee Type

- 304 Stainless Steel Carbonation Cap Tee Piece For Brewing to attach both gas and liquid

- [3 PCS] MRbrew Plastic Carbonation Cap Tee Adapter, Allow Gas In and Beer Out Simultaneously, Homebrew Kegging Soda Beer PET Bottles Ball Lock Type Counter Pressure Bottle Filling Cap 3-Way Connector

- New offerings regularly pop up. Search Amazon for “carbonation cap tee” to see what’s out there.

These caps along with tee fittings have proven to be very flexible. Here are some application ideas…

PET Bottles as Growlers:

Fill up a 1L or 2L PET bottle with your favorite homebrew. Put one of these on (purge the headspace by squeezing if you want to) and then pressurize for transport. This should help to reduce oxygen pickup and maintain carbonation levels.

This article contains affiliate links. We may make a small percentage if you use our links to make a purchase. You won’t pay more and you’ll be supporting Homebrew Finds and more content like this. Thank you for your support!

Fine Tune or Rapidly Carbonate Homebrew:

Fine tune or rapidly carbonate beer. You can also use this cap to rapidly carbonate beer. Same process as for transport, just set your regulator to the proper pressure and shake or agitate the PET bottle to help introduce CO2. Or hook it up to CO2 and let it sit in you kegerator.

Draft Line Cleaning Projects

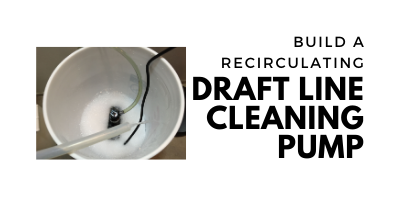

Clean kegerator lines are a key part of serving delicious beer. Bacteria and mineral build in lines can cause off flavors, quick loss of head, under-carbonated beer due to rapid co2 loss and lack of legs forming on the inside of your beer glass.

- Build A Recirculating Draft Line Cleaning Pump – a ground up build of a recirculating draft line cleaner. No hand pumps and cleans everything including the faucet!

- Mark II Keg and Carboy Cleaner Draft Line Cleaning Pump Conversion – a simple modification of the very popular Mark II Keg and Carboy Cleaner that allows it to clean beer lines. No hand pumps and cleans everything including the faucet!

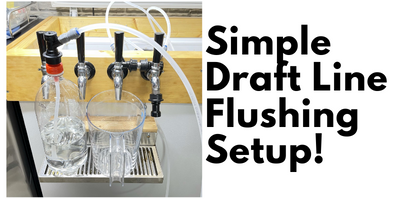

- Building a Simple Ball Lock Draft Line Flushing Setup – a quick line flushing setup. Not as robust of a setup, but I recommend this for a quick flush in between deep cleans

For these sorts of projects it’s important to source a carbonation cap that works with both LIQUID and GAS posts.

Convert a PET Bottle Into a Ball Lock Keg

You can use two carbonation caps along with a compatible tee and a length of tubing for a dip tube to convert a PET bottle into a ball lock keg.

Related: Hands on Review: Kegland Ball Lock Cleaning Kit

via William’s Brewing

- PET Bottle Dispensing Pump

- Ball Lock Cleaning Kit – includes pump, 2.5L PET Bottle & BLC

- 2.5 Liter PET Growler Bottles – via William’s Brewing

- Carbonation Cap Tee Adapter

- Red Carbonation & Cleaning Cap

via MoreBeer

- Ball Lock Line Cleaning Kit w/ Mini Party Pump KG503

- Carbonation and Line Cleaning Ball Lock Cap – Plastic FE133

- Carbonation Ball Lock Cap Tee Fitting KG501

Use a Carbonation Cap To Assist with Closed Transfer Racking

Thank you to Twitter Follower Josh @beardlywine for this tip! Let’s be friends! 8 Ways to Connect with HBF – Thanks John!

Thank you to Twitter Follower Josh @beardlywine for this tip! Let’s be friends! 8 Ways to Connect with HBF – Thanks John!

Josh uses carbonator caps to assist with closed transfer racking to kegs. If you look at the photo he shared, he’s putting a small length of tubing on the cap and then feeding that through the airlock grommet hole of his fermenter. This same process could be adapted to work with other styles of fermenters.

Gelatin Fining in a Cold Crash Primary Fermentation Keg – Chino’s Gelatin Cannon

This process is from /u/chino_brews via r/homebrewing. Published here with permission. Thanks you Chino_Brews!

This is a method to fine your beer with gelatin in an vessel that contains a ball lock post (or pin lock post) without opening the vessel and introducing oxygen (air). A Chino Cannon (aka Chino’s Gelatin Cannon) injects the gelatin solution into the vessel through the post.

It can be used to inject many other things into a keg, for exampe (1) Star San into a keg that has been pre-purged by filling with water and pushing the water out with CO2, (2) tinctures, extracts, flavorings, or other liquid flavor additions, or (3) priming syrup being injected for natural keg conditioning/carbonation.

Method

- Materials: (a) a barbed carbonator cap (see non-barbed variant) , (b) a small PET pop bottle with the same thread as a 2L Coca Cola bottle (PCO 1881 thread | Ø27 diameter 1881), such as a Dasani water bottle, (c) a short length of 5/16″ ID tubing that fits over the barb, (d) a jumper (see step 3), (e) a tool to vent the keg if it does not have a ring-pull pressure relief valve, and (f) gelatin solution. Ideally the type of carbonator cap that accepts a gas or liquid QD.

- Add Dip Tube to Carbonator: Add tubing to the barb so that when placed on the PET bottle it goes to a bottom “corner”. It is important to have the dip tube the correct length. You should cut a slight angle on the non-barb end of that tubing.

- Make a jumper: a jumper is a short length of tubing with a gas ball lock QD on one end and a QD that fits the carbonator cap for the other end. Connect the QDs with about 2-3 feet of tubing and whatever fittings you need (flare nuts, hose clamps, etc.) I strongly recommend using flare-type QDs for ease of cleaning, as mentioned below. VERIFY that the jumper is gas-tight and is not leaking.

- Fill Keg or other Vessel: Fill a pre-purged keg, give it just enough pressure to stay sealed after the temp drops, and then chill it. The beer can also be in another vessel that has a ball lock post, such as a conical fermentor or stainless steel brew bucket.

- Prepare Gelatin or other Injectable Solution: When the beer is chilled, heat some gelatin fining solution. When it gets to 130°F or less, pour it into the PET bottle, squeeze the air out, and cap it with the carbonator cap. MOVE QUICKLY from here on out. Note: PET melts around 140°F! The same process applies to priming sugar going into a keg. You do not need to heat other flavorings and can fill the bottle cold.

- Charge the Chino Cannon: Pressurize the PET bottle to a reasonably high pressure, 15-30 psi. Feel free to purge and fill as many cycles as your OCD about oxygen forces you to do.

- IMPORTANT: release the pressure on the keg.

- Connect the Jumper to the Chino Cannon: Hook up the jumper to the PET bottle. Hold the PET bottle upright so that the tubing inside is at the lowest level of the gelatin solution or other injectable. Now you have your Chino Cannon.

- Connect the Chino Cannon to the Keg or other Vessel Hold the PET bottle so that the dip tub is in the lowest “corner” of the PET bottle and hook the Chino Cannon’s gas QD to the keg. Watch the gelatin solution get rapidly shot into the keg! Feel free to rock the keg a bit to mix the gelatin with the beer if you want (not necessary IMO).

- Cleaning: remember that gelatin and other flavorings can literally be a nutrient for microbes. Furthermore, gelatin gels. It’s important to quickly disassemble and clean/rinse your Chino Cannon in HOT tap water while it’s still wet. It’s easy to clean now, but it will take more effort if you let the gelatin gel or sugars dry. This is where you’ll be happy if you used flare-type QDs so you can more easily get the residual liquid out with hot tap water. You’ll want to disassemble the QDs too.

More information: Photos, Video, a Non-Barbed Version and Troubleshooting Tips Chino Cannon (Chino’s Gelatin Cannon) via Reddit

Related: Five Benefits of Using Corny Kegs As Fermenters

Flush Keg Jumper Lines

This process is from /u/CascadesBrewer via r/homebrewing. Thanks you CascadesBrewer!

I have one connected to a short line of gas tubing and then to one of these disconnects. I can then hook that to my CO2 tank to flush CO2 through jumper lines, say when I transfer beer from one keg to another or the small jumper line I use to add gelatin into a keg.

Notes from HBF: With a universal carbonation cap (works with both gas and liquid QDs) you could use this same process to flush liquid jumpers with CO2. Another gadget that helps with flushing lines is Valuebrew’s Ball Lock Jumper. That allows you to easily couple from QD to QD regardless of whether they are liquid or gas. That means you can easily flush liquid and gas lines with CO2.

Sourcing a Carbonation Cap

- Ferroday Stainless Carbonation Cap Counter Pressure Bottle Filling With 5/16″ Barb – Hands on Review

- Stainless Carbonation Cap with 5/16″ Barb Ball Lock Type, Fit Most Soft Drink PET Bottles

- UP100 Line Cleaning Cap Stainless Carbonation Cap Counter Pressure Bottle Filling,w/ 5/16″ Barb

- 3pak PLASTIC CARBONATION & LINE CLEANING CAP,Carbonation Cap 1/4″ Barb, Ball Lock Type, Fit Soft Drink PET Bottles

- MRbrew Plastic Carbonation Cap, 3 PCS Ball Lock Keg Post 5/16” Beer Line Nipple Barb Homebrew Kegging Soft Soda Drink PET Bottles Counter Pressure Bottle Filling Cap with Spare Sealing Gasket O-rings

- MRbrew Plastic Carbonation Cap, 3 PCS Ball Lock Keg Post 5/16” Beer Line Nipple Barb Homebrew Kegging Soft Soda Drink PET Bottles Counter Pressure Bottle Filling Cap with Spare Sealing Gasket O-rings

- New offerings regularly pop up. Search Amazon for “stainless steel carbonation cap” to see what’s out there.

Tee Fittings

- Carbonation, Beer Brewing Carbonation Adapter 304 Stainless Steel Thread Conversion Connector Adapter Tee Type

- 304 Stainless Steel Carbonation Cap Tee Piece For Brewing to attach both gas and liquid

- [3 PCS] MRbrew Plastic Carbonation Cap Tee Adapter, Allow Gas In and Beer Out Simultaneously, Homebrew Kegging Soda Beer PET Bottles Ball Lock Type Counter Pressure Bottle Filling Cap 3-Way Connector

- New offerings regularly pop up. Search Amazon for “carbonation cap tee” to see what’s out there.

What Else?

Submit a Tip and Let us Know

Build a Simple Draft Line Flushing Setup

Keg Deals!

kegdealsBuild a Recirculating Draft Line Cleaner

Rebuild Your Kegs!

Also Consider:

Stainless Steel Ball Lock Jumper with Food Grade Silicone O-Rings: Allows you to connect multiple ball lock runs to clean multiple lines and taps at the same time. Works with both liquid and gas QDs. Stainless Steel Ball Lock Jumper – via Valuebrew – An easy add-on… food grade o-rings, featured in our Keg Rebuild Post

Stainless Steel Ball Lock Jumper with Food Grade Silicone O-Rings: Allows you to connect multiple ball lock runs to clean multiple lines and taps at the same time. Works with both liquid and gas QDs. Stainless Steel Ball Lock Jumper – via Valuebrew – An easy add-on… food grade o-rings, featured in our Keg Rebuild Post

More Homebrew Finds!

- Last 50 Finds!

- Top Deals – a curated list of the best deals

- Homebrew Reviews – one of the largest libraries of homebrew reviews in existence!

- Our Top Posts – tips, how-tos, resources posts and more

- Let’s be Friends!

Recent Deals!

Also: Kegerator Tips & Gear | Keg Repair Part #s | Recent Keg Finds

Our Top Draft Resources!

Check our our Top Draft Related Resources- Commentary: Pin Lock Keg Pricing and Availability

- Check Your CO2 Regulator for Leaks!

- How to get a keg ready for first use? New Keg Cleaning and Prep

- Portable Draft Beer Serving Options!

- Pin Lock Keg Pricing and Availability

- The Most Difficult Spot to Check for CO2 Leaks

- Keg O-Ring Materials Selection! – EPDM, Silicone and Buna-N?

- Why Do I Have Bubbles in My Beer Line? Diagnosing and Fixing Kegerator Foam Problems

- Five Benefits of Using Corny Kegs As Fermenters

- Rebuilding & Reconditioning Homebrew Kegs!

- Food Safe Replacement Keg O-Rings in Bulk

- Hands on Review: Kegland DuoTight Fittings & EVABarrier Tubing!

- Why Won’t My Beer Carbonate? Fixing Draft Beer Carbonation Problems

- What Does a Flow Control Faucet Do?

- Upgrade Your Kegerator – 6 Improvements!

- Serve Homebrew on Any Kegerator & Convert Commercial Kegerator to Homebrew

- Tips and Gear for Growler Filling

- What’s the Difference Between Ball Lock Kegs and Pin Lock Kegs?

- Checking for Draft System CO2 Leaks – Using The Pressure Gauge Method

- Tip: Consider Oetiker Stepless Clamps for Kegerator Gas and Beer Lines

- Hands On Review: Inkbird ITC-308 Dual Stage Temperature Controller +WiFi Version

- Universal Poppets Tips and Tricks!

- Convert Your Mark II Keg & Carboy Washer to a Recirculating Draft Line Cleaning Pump!

- Step by Step: Finding and Fixing Keg CO2 Leaks

- Kegerator Temperature Probe Placement – To Immerse or Not To Immerse? – three tests to determine optimal pla…

- Kegerator Beer Line Temperatures & Reducing Foam with a Recirculating Fan

- Kegging CO2 Use Estimations and Calculations

- Balancing Your Kegerator Draft System

- Building a Simple Ball Lock Draft Line Flushing Setup

- Build a Recirculating Draft Line Cleaning Pump

- Home Brew Keg Roundup – New & Used, 5 and 2.5 Gallon & More!

- Damp Kegerator? Fix Kegerator Condensation

- Homebrew Temp Controller Roundup! – Kegerator and Fermentation – concepts, applications and models

- Bulk Keg Orings and Keg Parts Reference

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdealsPrice, promotions and availability can change quickly. Check the product page for current price, description and availability.

Make sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions. tag:lnksfxd toppost:funwcarbcaps tag:tpr