Hands on Review: Brewers Hardware Tri-Clover Sample Valve

This review is by Homebrew Finds Contributor Brad Probert. Brad is an engineer, expert homebrewer and experienced reviewer. Grab a link to Brad’s website at the end of this review.

This review is by Homebrew Finds Contributor Brad Probert. Brad is an engineer, expert homebrewer and experienced reviewer. Grab a link to Brad’s website at the end of this review.

Brewers Hardware TC Sample Port

There are different types of valves, suited for different purposes. On a fermentor, it is useful to have a valve that has the ability to pull small samples for gravity readings or taste samples, but also able to flow well when it comes time for transfer to a keg. The sample port valve provides fine adjustment to flow rate, allowing you to vary between a slow trickle for pulling a sample or a higher flow rate for gravity transfer to fill a keg.

![]() Valve Handle with 2 O-rings and Silicone Seat

Valve Handle with 2 O-rings and Silicone Seat

The sample port valve has a fine pitch thread to allow for small adjustments to the opening of the valve. With the Brewers Hardware sample port valve, you can feel while turning the knob that the threads and the stem of the valve are machined to tolerances for a precise fit and without slop or wobble. The valve stem has 2 O-rings to keep beer from sneaking out or air sneaking in. And the tip of the valve has a silicone bumper that gets compressed onto a seat for a secure fit to prevent leaks when closed. Silicone is non-porous, making it easy to clean and not harbor stow-aways from one ferment to another. And its elasticity allows it to conform to the valve shape for a good seal, yet spring back so it can be used over and over again to seal and unseal.

The overall quality of the valve from Brewers Hardware was top-notch. The surfaces were smooth-polished stainless steel, and the ridges on the adjustment knob were cleanly machined for grip with no sharp edges. Turning the adjustment knob, it felt precise with no slop or wobble, with a tight seal. It’s difficult to give justice to the fit & finish of the part with just words or a couple pictures, but it really stands out.

Hands on Review

The TC flange on the valve made for a natural fit for the Spike Flex stainless bucket fermentor I had. The flange worked like all TC flanges I’ve used- easy and leak-free. I trialed the sample port as my outlet port on the fermentor. Here it served double duty- sample port to sneak tastes during fermentation, and for transfer of the fermented beer into my keg at the end.

Sample Port Installed on Spike Flex Fermentor – Hands on Review

Sample Port Installed on Spike Flex Fermentor – Hands on Review

My first batch ran into a snag that I corrected on my second batch. The Spike Flex has an angled pickup tube, and I fermented with this pickup tube angled slightly down (trying to avoid collecting yeast as it falls out of suspension). When I went to drain the fermentor, this created an airlock in the valve and beer wouldn’t flow out. When I rotated the pickup tube to point upwards, I heard the glug-glug of escaping air bubbles and then the valve flowed fine. I didn’t have this issue when using a large butterfly valve with the fermentor and the same orientation of the pickup tube, so I figure this must be due to the combination of the smaller passageway inside the valve. For the second batch, I had the pickup tube slightly above horizontal so any air bubbles could escape up, plus when filling I opened the valve slightly to ensure it was filled with beer. Not sure which was more significant, but I had no issues on that batch.

Post-Fermentation Sample Pulled for Gravity Check and Tasting

Post-Fermentation Sample Pulled for Gravity Check and Tasting

I don’t typically sample my beers during fermentation because I religiously use a Tilt Bluetooth hydrometer to monitor progression of my gravity. But the design of the sample port allows you to pull a sample at such a trickling slow rate, it would be great for those wanting to pull a sample for gravity checks. Of course it would also be great to monitor flavor maturation if you’re doing some kind of secondary process like soaking in oak chips or fruit. This valve truly makes those processes very low stress as you can get flow out of it at such a slow rate, you don’t risk overflowing any size sample glass/tube.

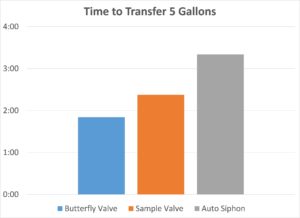

Plot of transfer times, click to enlarge

Plot of transfer times, click to enlarge

With this ultra-slow flow rate on one end, I was concerned that maybe in the full open position when transferring to a keg it would be frustratingly slow. It didn’t give me the feel of being slow, but being an engineer, I wanted to collect some data and compare transfer times with different equipment. I was surprised to find how similar the transfer times were between the sample valve and a large fully-opened butterfly valve.

For this experiment, I started with the Spike Flex filled up to the 6 gallon mark with water. I’d start the timer and immediately either open the valve fully (butterfly valve and sample port) or start pumping on the autosiphon (BrewSSSiphon). I then stopped the timer when I had collected 5 gallons. I was surprised to find that the sample valve was actually more like the butterfly valve for transfer times than the auto siphon.

Conclusions

Overall the valve performed just as well as it looked. The functionality of the sample valve was impressive with how well it was able to meter a flow rate from a trickle to a full stream with easy adjustment. And the transfer rate at full open was surprising when I timed it. The feel of the components, and the smoothness of operation indicated to me a well-machined valve whose quality was very apparent.

More Tri-Clover/Tri-Clamp! Tri-Clamp Fittings at Proflow Dynamics

More Photos

A look at Brewers Hardware Sample Valve

A look at Brewers Hardware Sample Valve Sample Valve TC Flange

Sample Valve TC Flange Close-up of Inside of Valve

Close-up of Inside of Valve

More Brewers Hardware Gear Reviews!

More Homebrew Finds!

- Last 50 Finds!

- Top Deals – a curated list of the best deals

- Homebrew Reviews – one of the largest libraries of homebrew reviews in existence!

- Our Top Posts – tips, how-tos, resources posts and more

- Let’s be Friends!

Recent Deals!

10 Most Recent Homebrew Resource Posts & How-To’s!

We are Homebrew Review HQ! Our 10 Most Recent Reviews

pinnedThis post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdealsSpecial Thanks to Brewers Hardware for providing the unit used for evaluation in this review.

By Brad Probert. Check out Brad’s website – beersnobby.com

Make sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions.

Price, promotions and availability can change quickly. Check the product page for current price, description and availability. tag:tpr review:bhtcsample