Hands On Review: Inkbird ITC-308 Dual Stage Temperature Controller

Updated: February 4, 2025

Inkbird’s ITC-308 Digital Dual Stage Temperature Controller is a dual stage, pre-wired Digital Temperature Controller

The ITC-308 comes in the original version as well as an updated Wi-Fi enabled model. This review covers both editions of this controller.

Why a Temp Controller?

Temperature controllers, sometimes referred to as over-riding thermostats, can control devices like refrigerators, freezers and fermentation heating devices to provide a consistent temperature for your kegerator, fermentation chamber or brew system. They do this by monitoring the temperature and cycling on and off the device in question. Generally, you will set the device to full cooling or heating power and the temperature controller takes over from there.

Limited Time Deal!

As of this update these controllers are on sale as part of a limited time and limited availability Lightning Deal. The ITC-308 is on sale for $24.50 and the ITC-308 +WiFi is on sale for $35. Lightning Deals are limited time and quantity deals and can change quickly. Check product page for current info – More About Prices

Deal is valid 2/4/25 only while supplies last.

Check Prices, Current Specs & Availability, Review Continues Below:

- Inkbird ITC-308 Digital Temperature Controller – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

- Inkbird WiFi ITC-308 Digital Temperature Controller – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

Alternate Listings:

- Inkbird WIFI Temperature Controller Reptile Freezer Thermostat ITC308 2.4GHz Digital Heating and Cooling Aquarium Heater Cooler Greenhouse Plug Outlet Probe Dual Stage 1100W 110V – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

- Inkbird ITC-308 Digital Temperature Controller Outlet Thermostat 2-Stage 1100W with Sensor Reptile Beer Brewing Kegs Fridge Cured Meat Breeding Growing – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

Different listings or combos for the ITC-308 may be available – search Amazon for “Inkbird Digital Temperature Controller” – to see what variations may be available

Canada:

At MoreBeer:

- Inkbird Digital Temperature Controller (WiFi Enabled) FE644

- Inkbird Digital Temperature Controller FE640

Our ITC-308 Deal Pages:

These pages show our most recent deals for these great controllers

Dual vs Single Stage

Dual stage means that the ITC-308 can control both a heating and cooling device. Alternatively, it can control a heating or a cooling device. This controller displays in Fahrenheit and Centigrade. Dual Display shows both measured and set temperature.

Hands on Review Inkbird’s ITC-308 Temp Controller

This article contains affiliate links. We may make a small percentage if you use our links to make a purchase. You won’t pay more and you’ll be supporting Homebrew Finds and more content like this. Thank you for your support!

A look at the box

A look at the box The controller body. The control has two readouts. The top is labeled PV. That stands for “Process Value” and displays the current temperature. The second reading is SV or Set Value. It displays the set temperature. There are two lights below those readouts indicating whether the controller is calling for cooling or heating. The unit has three buttons – SET, up and down. To get into settings hold the SET button down for 3 seconds. A short press of SET cycles through available settings while the up and down buttons change values.

The controller body. The control has two readouts. The top is labeled PV. That stands for “Process Value” and displays the current temperature. The second reading is SV or Set Value. It displays the set temperature. There are two lights below those readouts indicating whether the controller is calling for cooling or heating. The unit has three buttons – SET, up and down. To get into settings hold the SET button down for 3 seconds. A short press of SET cycles through available settings while the up and down buttons change values.

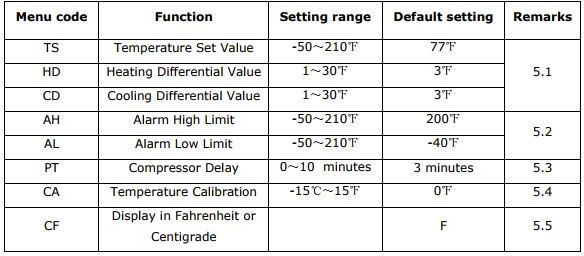

The ITC-308 has the following parameters – expand the section below to see the list. This list shows the menu abbreviation followed by the full setting name followed by a definition of what that setting means or does as best as I understand. Note that available options may change over time if Inkbird chooses to update software on this controller. Additional settings may be available for the Wi-Fi version.

Parameters and Descriptions

- TS – Temperature Set Value – Your target temperature

- HD – Heating Differential – Sometimes called offset by other manufacturers. This tells the controller how close you want to keep the temperature to the desired temperature set value. If you want it to stay very close, you would set it at 1 degree. That probably makes sense for fermentation. If you’re not as concerned you could let it wander a few degrees. That may make sense for your kegerators. Note: While some controllers have only a single offset or differential value that applies to heating and cooling, the ITC-308 breaks this out into both heating and cooling variables. The HD figure applies while heating, while while the CD figure applies when cooling. Here is an example from the manual – “For example, set TS=25°C, CD=2°C , and HD=3°C, then when measured temperature is higher or equal to 27°C(TS+CD), system enters refrigeration status; when temperature decline to 25°C(TS), stop refrigeration; when measured temperature is lower or equal to 22°C(TS-HD, system enters heating status; when the temperature raised to 25°C(TS), stop heating.”

- CD – Cooling Differential – See HD for a description of CD

- AH – Alarm High Limit – When measured temperature is higher or equal to AH, high temperature alarm will be triggered.

- AL – Alarm Low Limit – When measured temperature is lower or equal to AL, low temperature alarm will be triggered

- PT – Compressor Delay – Sometimes called Anti-Short Cycle Delay by other manufacturers – This is an important feature that helps to protect your freezer or refrigerator’s compressor. This setting (usually expressed in minutes) tells the controller the minimum amount of time to let the compressor rest. This is regardless of other settings. Example: ASD set to 5 minutes. The cooling cycle has just kicked off on your chest freezer based kegerator and you open the lid. One minute later the probe has warmed up and is again calling for cooling… Nothing happens until the 5 minutes has passed. Overriding temp controllers are asking cooling devices to do something they may not have been engineered for. A typical chest freezer cycles on only rarely when used as a freezer. Setting these to a 1 degree offset for fermentation temp control isn’t exactly what the engineers had in mind. ASD helps mitigate that issue and extend the life of your device. From the manual: “Under refrigeration mode, after power on, if the measured temperature is higher than the value of setting temperature(TS) plus cooling differential(CD), the equipment won’t start refrigeration immediately, but waiting for a delay time.”

- CA – Temperature Calibration – Use this setting to calibrate or correct the controller. From the manual: “When there is deviation between measured temperature and actual temperature, use temperature calibration function to align the measured temperature and actual temperature. The corrected temperature is equal to temperature before calibration plus corrected value( corrected value could be positive value, 0 or negative value)”

- CF – Temperature Unit C or F – Change the display between Fahrenheit and Celsius

ITC-308 value ranges in Fahrenheit Mode. Consult Manual for Centigrade Ranges

ITC-308 value ranges in Fahrenheit Mode. Consult Manual for Centigrade Ranges

A look at the power and temperature cables

A look at the power and temperature cables A look at the 5′ temperature cable

A look at the 5′ temperature cable The manufacturer says that the temperature probe is waterproof and submersible. I’ve found that to be true. Here is the probe submerged in a growler. I left it submerged for a couple weeks and it continued to work as expected.

The manufacturer says that the temperature probe is waterproof and submersible. I’ve found that to be true. Here is the probe submerged in a growler. I left it submerged for a couple weeks and it continued to work as expected. Here’s a look at the plug in cable. It has two outlets, one labeled cooling and one labeled heating. Plug your cooling device (typically a refrigerator or freezer) into the cooling device and your heating device into the heating outlet. You can also leave either unplugged if you’re only interested in heating or cooling. By using both a heating and cooling device you can really dial in fermentation temperature. Or, if you’re running a kegerator, you’re probably only interested in cooling. The Itc-308 and similar controllers are sometimes called overriding temperature controllers. The thermostat in this unit essentially takes over control from your heating or cooling device by cycling on and off the power as needed.

Here’s a look at the plug in cable. It has two outlets, one labeled cooling and one labeled heating. Plug your cooling device (typically a refrigerator or freezer) into the cooling device and your heating device into the heating outlet. You can also leave either unplugged if you’re only interested in heating or cooling. By using both a heating and cooling device you can really dial in fermentation temperature. Or, if you’re running a kegerator, you’re probably only interested in cooling. The Itc-308 and similar controllers are sometimes called overriding temperature controllers. The thermostat in this unit essentially takes over control from your heating or cooling device by cycling on and off the power as needed.

In this picture, I’m using a Lasko MyHeat 100 to keep my fermentation temp up. Note: Always read and follow manufacturer’s directions. If you’re looking for something for the heat side of the equation, check out something like a Homebrew Fermentation Heater

In this picture, I’m using a Lasko MyHeat 100 to keep my fermentation temp up. Note: Always read and follow manufacturer’s directions. If you’re looking for something for the heat side of the equation, check out something like a Homebrew Fermentation Heater

A look at the display in the dark

A look at the display in the dark

Back of the unit. Displays some specifications and additional information.

Back of the unit. Displays some specifications and additional information. The mounting hole in use. A screw is not included.

The mounting hole in use. A screw is not included. I tested accuracy using an ice water bath. Here is the probe submerged in an ice water bath housed in a Spiegelau Stout Glass.

I tested accuracy using an ice water bath. Here is the probe submerged in an ice water bath housed in a Spiegelau Stout Glass.

The ice water reads 32.5 deg F. That’s within .5 deg F and relatively impressive. For a point of reference, that beats the stated accuracy tolerance for both the CDN-DTQ450X (+ or – 2 deg F) and the Thermapen Mk4 (+ or – .7 deg F). The ITC-308 can also be calibrated if necessary.

The ice water reads 32.5 deg F. That’s within .5 deg F and relatively impressive. For a point of reference, that beats the stated accuracy tolerance for both the CDN-DTQ450X (+ or – 2 deg F) and the Thermapen Mk4 (+ or – .7 deg F). The ITC-308 can also be calibrated if necessary.

One of the first things I used this for was maintaining temperature while carbonating with my Spunding Valve. See: Build a Spunding Valve

One of the first things I used this for was maintaining temperature while carbonating with my Spunding Valve. See: Build a Spunding Valve Fermenting Great Fermentations’ “Piney the Welder“

Fermenting Great Fermentations’ “Piney the Welder“ Fermenting Great Fermentations’ Dark Side Robust Porter

Fermenting Great Fermentations’ Dark Side Robust Porter

Hands on Review Inkbird ITC-308 WiFi

Inkbird introduced an updated version of the ITC-308 with WifFi functionality in the first quarter of 2019. This addendum is by Homebrew Finds Contributor Brad Probert. Brad is an engineer, expert homebrewer and experienced reviewer.

In Action Fermenting Using a Spike Brewing Flex Fermentor – Hands on Review

In Action Fermenting Using a Spike Brewing Flex Fermentor – Hands on Review

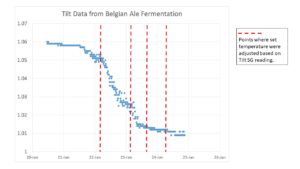

After using the Tilt Bluetooth Hydrometer on many fermentation batches, being able to have continuously updated gravity readings has opened up new possibilities for me during fermentation. While monitoring the trends in gravity over time, I can see when fermentation rate is starting to slow, and I can step in and bump up the temperature to keep things moving along. This is what I do on all my fermentations now. Start at a temperature on the low end of the yeast’s temperature range, and then just keep tabs on the gravity drop rate.

Tilt Data Plot (click to enlarge) – shows temp adjustment points – Hands on Review Tilt Bluetooth Hydrometer

Tilt Data Plot (click to enlarge) – shows temp adjustment points – Hands on Review Tilt Bluetooth Hydrometer

However, I developed a new type of FOMO (Fear Of Missing Out). I’d now be sitting at work checking the progress of fermentation and then be thrown into a panic because I could see the gravity starting to slow down and I was helpless at work, not able to bump up the temperature. I’ve even called home when I was out of town and talked my 12-year old son through the process of how to increase the set point temperature. So when I saw Inkbird had a Wi-Fi controller, I was excited.

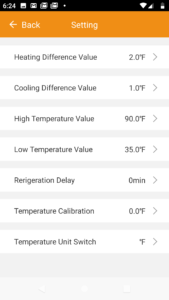

App Screenshot – heating active mode

App Screenshot – heating active mode App screenshot – settings

App screenshot – settings Heating and Cooling Outlets

Heating and Cooling Outlets Temp Probe

Temp Probe

The controller works exactly like the regular ITC-308 controller with easy temperature set point adjustment, a hardwired temperature probe included, and a receptacle that has both a Cooling and Heating plug. With the Wi-Fi feature, a one-time setup process done via a downloaded App on your phone gives you the ability to check the temperature reading and adjust the set point temperature up or down remotely via your smartphone. So now, whenever I check the gravity from my Tilt reporting, if I see I need to adjust the temperature, I just switch over to the Inkbird app and adjust it. Totally simple, and no more FOMO.

Conclusions

The ITC-308 by Inkbird is a great temperature controller. It is accurate, easy to use, has great features and is reliable. Because of it’s features and general price, I called this a game changer when it first came out. After using it for years, I will stand by that. As far as comparing general price and features to other controllers, as of this writing, I don’t know of anything that’s close to the Inkbird ITC-308.

After years of using the original ITC-308 temperature controller, I can heartily recommend it to you to aid with fermentation and kegerator temperature control. I think the ITC-308 is an outstanding choice.

Check Prices, Current Specs & Availability:

- Inkbird ITC-308 Digital Temperature Controller – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

- Inkbird WiFi ITC-308 Digital Temperature Controller – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

Alternate Listings:

- Inkbird WIFI Temperature Controller Reptile Freezer Thermostat ITC308 2.4GHz Digital Heating and Cooling Aquarium Heater Cooler Greenhouse Plug Outlet Probe Dual Stage 1100W 110V – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

- Inkbird ITC-308 Digital Temperature Controller Outlet Thermostat 2-Stage 1100W with Sensor Reptile Beer Brewing Kegs Fridge Cured Meat Breeding Growing – affiliate link, note that multiple variations of this product may be available, as such a different version may appear at this link

Different listings or combos for the ITC-308 may be available – search Amazon for “Inkbird Digital Temperature Controller” – to see what variations may be available

Canada:

At MoreBeer:

- Inkbird Digital Temperature Controller (WiFi Enabled) FE644

- Inkbird Digital Temperature Controller FE640

Our ITC-308 Deal Pages:

These pages show our most recent deals for these great controllers

Related Resources:

- ITC-308 User Manual

- Looking for a Deal? Inkbird Temperature Controller Deals and Reviews

- Maintaining Fermentation Temps in Colder Weather

- Homebrew Hack: Mimicking Dual Stage Temp Control with a Single Stage Controller

- Homebrew Temp Controller Roundup! – Kegerator and Fermentation – concepts, applications and models

- Kegerator Temperature Probe Placement – To Immerse or Not To Immerse?

- Yeast Starters & Fermentation Resources

- Kegerator Tips & Gear

More Homebrew Finds!

- Last 50 Finds!

- Top Deals – a curated list of the best deals

- Homebrew Reviews – one of the largest libraries of homebrew reviews in existence!

- Our Top Posts – tips, how-tos, resources posts and more

- Let’s be Friends!

Recent Deals!

10 Most Recent Homebrew Resource Posts & How-To’s!

We are Homebrew Review HQ! Our 10 Most Recent Reviews

pinnedThis post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

greatdealsSpecial Thanks to Inkbird for providing the WiFi unit used for evaluation in this review.

Make sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions. tag:lnksfxd review:itc308 rs:8 #tag:tpr

I just built a small walk in cooler. I bought 2 ink bird 308 can I put the one probe to make the a.c. to go cooler and the probe for the other one in the fins of the a.c.. Should the one be plugged into the other on on cooling?

I think you’d only need one controller in this situation. Maybe I’m not understanding what you’re trying to do.

Hello,

Thank you for the writeup. Is there any possibility this will burn out the freezer? Any precautions I will have to take to avoid that? Anyway to prevent molding or mildew from the high/low drops?

Thank you!

It is possible that this will burn out the compressor. The Inkbird has an anti short cycle delay setting that is intended to limit the number of times the compressor kicks on and off. As far as condensation goes, check this out… https://www.homebrewfinds.com/handling-kegerator-condensation-eva-dry/

Could I use this with a1500w heat stick to heat mash water and boil wort?

No, that exceeds the rated capacity for this controller.

Sorry, if this is a dumb question, but could you please define the menu options? I’m guessing the temperature set value is the value you want your fermenter to be at…….can you confirm the others pls?

That’s a great question Pete. I added descriptions of those along with a chart of possible values. Cheers!

I’m keen to know what’s the better setting to not overwork my refrigerator.

Does setting the delay to 0 not put undue load on the compressor?

Potentially, that’s what the anti short cycle setting is about.

I think installing sensor inside a water vessel is a good choice. Moreover if you use to open door sometimes. People that says 10 degrees difference between fermentator and inside air maybe is because are reading with door open. If 10 degrees is right, test the oppose: when you read with thermowell the water is coldest by 10 degrees? I don’t think so. Fermentation is exothermic but the power of freezer will put the system in thermal equilibrium for sure.

Could you use this as a double heating or double cooling thermostat?

Thermostat Setting #1 – on at 85 off at 120 (runs standard heat exhaust fan)

Thermostat Setting #2 – on at 90 off at 120 (runs secondary excess heat exhaust fan)

Thank you

If I’m understanding you correctly, no I don’t believe that would work. You’re suggesting two upper limits, this unit has an upper and lower limits, one for a heating cycle and one for a cooling cycle.

Hi!

Nice review!

I just recently started to use this inkbird and for me; so far so good!

I set the HD to 0,5 C just to try it…

guestion:

Should i let the fridge run on high level (set to be really cold) or is it better to let it cool down slower by setting the fridge on low level?

It would be interesting to learn how this affects the temp profile.

I used duck tape to attach the probe on my fermentation bucket….

I believe the general advice is to run it on high (highest cooling ability). That’s what I do with my deep freeze and it has worked dandy for me for a long time.

I have one of these on order, and am looking forward to using it soon. Looks like a very good value for the money.

I’d be careful about submersing the insulated wire portion of the temp probe into the beer. Some Chinese wire insulation has been found to contain lead. They make a unit with a 12″ stainless steel probe which would be safe. Granted, the trace amounts of lead are probably not as bad for you as the alcohol, but it’s something to consider.

I think taping or rubber banding to probe to the outside of the fermenter would give a fairly accurate read of the fermenting beer inside. Others have said they put the probe in a separate glass of water. That’s not a great idea, since the fermenting yeast can raise the temp in the wort by 5-7 degrees. That won’t be measured in a separate glass of water.

I like that the cooling circuit has a programmable delay to protect the compressor.

I wish this item was UL tested and certified.

Hey man. I just bought one of these and am using it with a chest freezer and a fermentation heating pad I got from a homebrew supply shop. I set it up for 1 degree of differential and it seems to be working well. However, with the chest freezer, it seems to drop several degrees below my desired fermentation temp before it ramps back up to the temperature I want. Any idea how to make it more consistent and not drop so low?

Hey Bryan! Glad it’s working well for you. The setting you want to change is called “Heating Differential” That tells the thermostat how much of a swing you want have. Stated another way, how close you want the temperature to stay to where you’ve set it. For fermentation, I have mine set at 1 deg F. Hold down the SET button for 3 seconds to get into the menu. The first value is TS = Temperature Set Value. Hit Set to go bask that. The next one is HD or Heating Differential. That’s the value you want to change. Hold down set again for 3 seconds to save you changes.

I’m using the ITC-308 with a chest freezer for a fermentation chamber. Should I use a warming wrap or something to add warmth when needed? In the summer I’ll use the chest freezer and in the winter I’ll ferment in the garage.

Hey John! That’s a great question. I would say a heating source is helpful year round. Not 100% required, especially in warmer times of the year, but certainly helpful. A heating source gives the ITC-308 a tool to use to really keep temperatures in line. It’s also handy for times that you actively want to drive up fermentation temps, let’s say during a diacetyl rest or to try and keep fermentation actively going, if the yeast are wanting to quit early. Check out this post for some of the heating options that are our there.

Good write-up. I bought one of these to try up against my A419 single stage. At the price point it sells at, I expected it to be disposable low-end Chinese manufacturing. I’ve used it for two batches now. One Saison that was fermented at warmer temps and one lager. So far, I have to say, I’m impressed. A 2-stage controller that costs less than my single stage A419, and so far is working as well. Thanks for the tip on the the probe being waterproof too. I didn’t realize that.

Do you know what happens to the power of the plugged in heat and cooling sources if the unit fails? Will they both go on or both stay off? Or is this a setting?

I ended up returning mine. I found the quality of the build to be lousy…horrible directions, totally vague, and very frustrating. For those who want to suffer with this quality and figure it out, I’m sure it’s a great product. But based on some other reviews, and the fact that I invest way too much time and passion into my beer to compromise on quality, I would spend the extra dollars and get a Ranco or Johnson device…made here int he good ‘ol USA, and totally reliable…

It’s a preference, so not trying to judge, but I’m not buying the hype on this cheaply made Chinese crap….

Haha what?? It took me longer to open the packaging and box than to get it running. Pretty simple and if not, there’s sites like this that lay it out even easier.

Surprised you struggled with this – I found it pretty much plug & play. The unit itself is of excellent quality and I’m very happy with it, a friend of mine owns a Ranco and he is selling his to buy an Inkbird!

Inkbird makes a unit with a 12″ stainless probe that is replaceable. The model is : Itc-308S They also sell a 2″ replacement probe (NTC-5CM) that fits perfectly into a SSTECH brew bucket thermowell. I’m really happy with set up. Near perfect temperature control.

Just bought one and installed an SS thermowell in the side of my bucket, along with a FermWrap in my 55degF basement. I’ve dropped a temp. logger in the water to monitor the controller’s performance. I get some (albeit minimal) overshoot. I’ve changed the heating dead band to 1degF. Setting a set point of 67 usually overshoots to about 68.2.

Any experience with how it varies between just water vs. actively fermenting wort? And advice on settings?

Because of your post and review of the product, I bought this unit. Great review, and so much cheaper than a Johnson. I appreciate you finding this!

Thanks for the write up. I just received my 308 and was wondering if you changed any of the setting values for compressor delay, heat and or cool differential value for fermentation? I’d like to keep the beer within one degree and not have it alternating between cool and heat constantly. Thanks!

Hey Jason! The only setting I changed for fermentation was… I changed the offset to 1. I don’t think you should have a problem with the heating and cooling cycles “fighting”, I have not. If do have that, you could change the offset to 2.

Where do you put the temperature probe? I use both glass and plastic carboys (and occasionally a large Speidel) and I tape the probe to the vessel and cover it with a small tissue pack to add some insulation. At the end of the day though I am reading the temp of the vessel and not the contents. My thoughts are that there isn’t likely to be a significant difference between the two temperatures. Thoughts?

Hey Dean! I usually either tape or rubberband (big rubberbands) the probe to the side of my fermenter. The fermenter and beer constitute a relatively large amount of mass. I really don’t think there is a huge difference from the side of the vessel and the thermowell. I heard of someone (maybe Jamil Z?) doing a test on this and finding the temperatures were close. I wish I had some more concrete numbers to give you, but for me… I put it on the outside of the fermenter and feel like that works well.

I use a beaker full of water to put my sensor in. The water should be very close to the brew temp, plus, it’s more stable and doesn’t turn on the heat or cooling as much!

For ambient temps you are correct, however while the beer is in fermentation phase I find that the temp variation can be as high as 10 degrees. So if you seek to maintain beer fermentation at a set value the only way I’ve found to do so is with a thermowell in my bucket lid ($12). I’ve tested using the method of taped to side of bucket/carboy, in a vessel of liquid and in the thermowell. So far thermowell is best for my systems when wanting to maintain temp of the wort/beer.

Just my experience.